nano size material by ball milling

Shaker Mill, High Energy MIlling, ball milling for nano ...

Shaker Mill,High Energy Milling,Ball Milling For Nano Structure Materials, Find Complete Details about Shaker Mill,High Energy Milling,Ball Milling For Nano Structure Materials,Shaker Mill Ppfug Ppf Ug from Grinding Equipment Supplier or ManufacturerJantek Nano Machinery

الحصول على السعر

FABRICATION OF A DISORDERED AND NANOGRAIN SIZED .

fabrication of a disordered and nanograin sized feal intermetallic alloy by two ball milling conditions: microstructural characterization and crystallite modeling perspective r. a. rodrÍguezdÍaza, juan fraustosolisa*, a. sedanob, a. molinab, j. porcayocalderÓnb, j. juarezislasc

الحصول على السعر

The Structure and Mechanical Properties of HighStrength ...

combination of highenergy ball milling and subsequent spark plasma sintering. The average grain sizes of the ultrafinegrained and microcrystalline materials were 200 nm and 1 m, respectively.

الحصول على السعر

Emax High Energy Ball Mill Retsch

The High Energy Ball Mill Emax combines highfrequency impact, intensive friction, and controlled circular jar movements to a unique and highly effective size reduction mechanism. The grinding jars have an oval shape and are mounted on two discs respectively which move the jars on a circular course without changing their orientation.

الحصول على السعر

Preparation of Starch Nanoparticles via HighEnergy Ball ...

The deposited Ni nanoparticles onto the CNTs were 50nm in diameter without ball milling, but they increased in size with increasing milling times up to 120nm. Also, the milled CNTs were damaged and changed from its original morphology due to the high ball milling energy.

الحصول على السعر

Syntheis methods ( Ball milling Method CVD methods)of ...

Mar 26, 2019· Ball Mill Principle, Advantage, Disadvantage ... Size reduction equipment2 ... Simple And Cheap Method For The Mass Production Of Metal Nano Particles Duration: 6:19. Robert MurraySmith ...

الحصول على السعر

Structurecontrolled Nanomaterial Synthesis using ...

Keywords:Ball milling, bulk materials, coldwelding, micro/nanostructured materials, plastic deformation, surfactant assisted mechanical milling. Abstract: The applications of nanoparticles have been tremendously increased in the field of targeted drug release, gene silencing, therapeutics, industrial and environmental catalysis, water ...

الحصول على السعر

cost of ball grinding mill to produce nano size particle

Planetary Ball Mills like pulverisette 4, pulverisette 5, pulverisette 6 and pulverisette ... the material adheres to the bowl wall and the grinding balls and it is ... minutes (line 5) that has the appropriate particle size for further attempts to produce Nano ... walls and thus provides the best cost/performance ratio of any mill available.

الحصول على السعر

Combustion combined with ball milling to produce nanoscale ...

to produce nanoLa 2 O 3 powders. Peparr ation of spinel LiMn 2O 4 The LiMn 2 O 4 powders were synthesized by highpressure spray drying assisted with solidphase sintering. Li 2 CO 3 (Tianqi) and electrolytic MnO 2 (Aldrich) were mixed in deionized water at a Li:Mn molar ratio of :2, after ball milling with a vertical ball mill for 2 h.

الحصول على السعر

Manufacturing nanosized powders using salt and sugar ...

Manufacturing nanosized powders using salt and sugarassisted milling Shruti Gour Advisor: Dr. Yury Gogotsi There is need for nontoxic, biocompatible nanoparticles for various applications in the field of nanoengineering. Reduction of size to nanoscale is required to enhance material

الحصول على السعر

Combustion and Ball Milled Synthesis of Rare Earth Nano ...

high energy ball milling and combustion synthesis are the most useful techniques for producing nanosized ceramics and ceramiccomposites. The ball milling technique is more environmentally safe than the method of chemical synthesis, producing far less chemical waste [1]. A number of nanostructured metal oxides and their solid

الحصول على السعر

Magnetic properties of nanosized 5 at.%FeAl systems

Abstract High energy ball milling is a promising materials processing technique that is widely used to produce nanocrystalline structures. However, when stainless steel or hardened steel containers and balls are used for milling, contamination from the milling medium can influence the material properties of the final nanostructured products due to intercalation of iron (Fe) as an impurity.

الحصول على السعر

CNA Preparation method of lithium iron ...

The invention discloses a preparation method of a hightap density lithium iron phosphate material. The method comprises the following steps: mechanically mixing iron orthophosphate, a lithium source and a composite carbon source, transferring to a wet stirring ball milling device, adding a certain amount of deionized water and dispersant to form uniform suspension liquid, carrying out nano ...

الحصول على السعر

Frequency and temperature dependent electrical ...

Frequency and temperature dependent electrical characteristics of CaTiO3 nanoceramic prepared by highenergy ball milling Subhanarayan SAHOOa,*, Umasankar DASHb, S. K. S. PARASHARc, S. M. ALIa aSchool of Electrical Engineering, KIIT University, Bhubaneswar 751024, India bCenter for Nanotechnology, KIIT University, Bhubaneswar 751024, India

الحصول على السعر

Nano Ball Milling Price

Nano ball milling ball milling 1 ball milling method by aravind n b 2 nano materials can be defined as those materials which have structured components with size less than 100nm at least in one dimension nanotechnology is an advanced technology, which deals with the synthesis of nano.

الحصول على السعر

Onepot synthesis of highly active Ni/Fe nanobimetal by ...

neous ball milling and in situ chemical deposition process (BC) to prepare the nanoNi/Fe bimetallic can effectively resolve the problems mentioned above. The objective of the present study was to evaluate the performance of nanoNi/Fe bimetallic material prepared by simultaneous ball milling and in .

الحصول على السعر

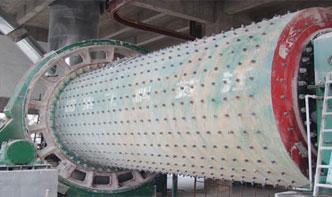

The operating principle of the ball mill

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

الحصول على السعر

Microsized TiO2 activated by highenergy ball milling as ...

In our opinion, using microsized TiO 2 as starting materials is an efficient way to reduce the preparation cost of Li 4 Ti 5 O 12. After activated by highenergy ball milling, microsized TiO 2 has lower degree of crystallinity and smaller particle size, which is beneficial for the synthesis of Li 4 Ti 5 O 12.

الحصول على السعر

Nanomaterials PPT and PDF Report Free

May 15, 2017· The meaning of the word nano is 10^9 and one nanometer is equal to a billionth of a meter. If an object's material size is decreased to nanoscale then the material of object exhibits distinct properties when compared with the properties of the material in bulk form.

الحصول على السعر

synthesis of nanomaterials by ball milling

SYNTHESIS OF NANO PARTICLES BALL MILLING . PRODUCTION OF NANO MATERIALS: BALL MILLING METHOD BY 10311A1903 ECM D1 INTRODUCTION Nano materials can be defined as those . » More; ball milling method of preparation of nanomaterials. High energy ball milling process for nanomaterial synthesis.

الحصول على السعر

Mechanical milling of aluminum powder using planetary ball ...

operating conditions (milling time, ball size, PCA and speed) in Al matrix to achieve particle size reduction. 2. Experimental details Planetary ball milling is carried out for fabrication of engineering materials via a mechanical alloying process. In planetary ball milling, the milling .

الحصول على السعر

Nitrogendoped graphene by ballmilling graphite with ...

containing 200 stainless steel grinding ball (5mm). The bowl was sealed followed by fixing it in the planetary ballmill machine. The mixture was ball milled at 500rpm for 48h. After the ball milling, the asprepared product was washed with hot water (80°C) for 5 times, followed by dispersing in water (1mgmL−1)andultrasonicatedfor2h(Scheme1(b))

الحصول على السعر

nano ball milling

Ball Milling Of Nano Materials Slides. Nano Ball Milling SlideShare Dec 15, 2012 BALL MILLING METHOD By Aravind N B Nano materials can be defined as those materials which have structured components . ... The effort to grind that stuff to nano size, (especially after highenergy ball milling .

الحصول على السعر

Development of nanooxide dispersed 304L steels by ...

among the powder particles in a high energy ball It has been repeatedly proven that reduction of grain size can substantially improve properties of the alloy. By using simple equipment a planetary ball mill, powders of few microns size can be brought to nano sized level, hence a nano structured stainless steel is In ...

الحصول على السعر