spaindas balls in cement ball mills

Ball Mills Used In Cement Plants

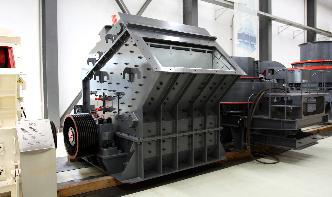

ball mill of cement plant Cement Ball Mill. Overview. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to .

الحصول على السعر

Sell Cement Production Line, Cement Equipment, Cement Ball ...

More Cement Line Equipment Ball Mill Plant: Ball mills [499] Cement Line Equipment Photos Catalog Cement Line Equipment Business Cards Cement Line Equipment Members Directory Cement Line Equipment Videos Cement Line Equipment email alerts Offers .

الحصول على السعر

grinding balls for cement ball mill

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering A ball mill works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow ...

الحصول على السعر

HOW BALL MILL WORKS?

Oct 10, 2016· The balls impact on the milled material longer at the pipe ball mills. The drum of these mills lined with flint blocks inside or flint pebbles on the cement. Material continuously fed by the drum axis through a hopper at one end and leaves at the opposite end of .

الحصول على السعر

Material For Balls In Ball Mill Concrete

The ball mill grind various ores and other materials either wet or dry. There are two kinds of ball mill, grate type and overfall type due to different ways of discharging material. There are many types of grinding media suitable for use in a ball mill, including ceramic balls, flint pebbles and stainless steel balls.

الحصول على السعر

Forged steel balls used in mines, cement, power station ...

Equipment For Casting Grinding Balls. AUTOMATIC CASTING GRINDING MEDIA BALL MOLDING LINE; TILTING TYPE POURING SYSTEM; MEDIUM FREQUENCY INDUCTION FURNACE; BALLS SEPARATING AND SORTING MACHINE; Heat Treatment Equipment. ELECTRICAL TYPE HEAT TREATMENT MACHINE; GAS TYPE HEAT TREATMENT MACHINE; Equipment For Forging balls. AUTOMATIC HOT ROLLING .

الحصول على السعر

Ball Mills PSP Engineering

Ball mills Ball mills are used for dry and wet grinding of different materials such as cement materials, cement, lime, and ceramic materials. PSP Engineering has continuously refi ned the design of its ball mills. Horizontal ball mills have become a reliable part of grinding plants Main characteristics of ball mills seated on shoetype bearings

الحصول على السعر

Ball Mills Mine

Grinding Ball Mills. A Ball Mill grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground. The rotation is usually between 4 to 20 revolutions per minute, depending upon the diameter of .

الحصول على السعر

Cement Mill Grinding Media Page 1 of 1

Nov 01, 2017· Cement Mill Grinding Media. Dear Experts, I want to know about the GM size wise percentage distribution in a 2 chamber close circuit OPC ball mill. Mill dim. x Media load 128 MT high chrome. Also let me know how do the supplier selected 80mm as max. Ball size in this mill? Please share the formula as well.

الحصول على السعر

What is a ball mill? What are its uses and advantages? Quora

Sep 04, 2018· A ball mill works on the principle of impact; where the grinding media is the balls, which may be made of steel (chrome steel), stainless steel or rubber. The ball mill is a key equipment extensively used for grinding crushed materials in production lines for powders such as cement, fertilizer, refractory material, silicates, glass ceramics as well as for ore dressing of both...

الحصول على السعر

Ball Mill Dynamics Clinker and Cement

Sep 11, 2018· Ball Mill Dynamics The basic objectives of ball milling is the size reduction of materials, called comminution. Size reduction in a ball mill is achieved primarily by the motion of the balls in the mill. By rotation, the mill elevates the ball charge and material and drops the load upon itself.

الحصول على السعر

JoyalBall Mill,Ball Mill For Sales,Ball Mill Manufacturer

Ball mill is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry grinding. Besides, it is mainly applied in many industries, such as ferrousnonferrous metal mine, coal, traffic, light industry, etc.

الحصول على السعر

Radiotracer Investigation of Clinker Grinding Mills for ...

ball mill and the separator (Plasari and Theraska, 1981). Cement cli nker is usuall y grounded using a ball mill. This is essentially a large rotating drum (Fig. 2), containing grinding media; normally steel balls (Fig. 3). As the drum rotates, the motion of the balls crushes .

الحصول على السعر

cement plant ball mills

Cement mill Wikipedia, the free encyclopedia. A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills ....

الحصول على السعر

Grinding Media Grinding Balls | Union Process, Inc.

Shape – balls, beads and satellites satisfy the bulk of our customers' requirements, but we also source highly specialized shapes like ballcones and diagonals Diameter – depending on the material, ranging from mm to 2 mm for small media mills, up to 1/8" to 1" for traditional Attritors and up to ½" to 2" for ball mills

الحصول على السعر

Balls and Spheres etc

Jan 28, 2016· MILLING BALLS Milling balls were and still are used in rotating drums known as ball mills, to reduce the size of particulate materials by tumbling and grinding. Older examples were made from hardstones including agate and flint or as ceramics from fired .

الحصول على السعر

Ball Mill Load feed International Cement Review

Dec 03, 2010· Re: Ball Mill Load feed Dear xxxx, When the mill is chocked it only rotates like a feed material + balls thrown cetrifugally outward toward mill liners and remain stick over is no grinding process going on but a "choked process".

الحصول على السعر

balls used in cement ball mill

Difference Between Sag Mill vs Ball Mill mech4study. Oct 12, 2017Ball mill is a fine grinder. A horizontal or vertical rotating cylinder which is filled partially with the balls of ceramics, small rocks and balls made from stainless steel. The ball charge of a SAG mill is about 29% to 30%.

الحصول على السعر

Ppt On Ball Mill Grinding Media In Cement Industry

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

الحصول على السعر

Grinding Mills: Ball Mill Rod Mill Design Parts

In the cement industry, a ball mill for this application is called a Preliminator mill. Concavex grinding medium is an improved type of ball grinding media which offers more surface area per unit of weight, and has found extensive use in the grinding of cement clinker.

الحصول على السعر