cement manufacturing process with gypasum

Production of Beneficiated Phosphogypsum for Cement ...

The beneficiated phosphogyp sum was used for making portland cement and portland slag cement. The results favour use of phosphogypsum as an additive to cement clinker in place of natural gypsum. Introduction About mt of phosphogypsum is produced as byproduct from the phosphoric acid industries in India annually.

الحصول على السعر

Production process of Mir Cement | Mir Cement Limited

Cement Finishing Process: The final process of cement making is called finish grinding. Clinker dosed with controlled amount of gypsum is fed into a Ball Mill, a horizontal steel tube filled with steel balls. As the tube rotates, the steel balls tumble and crush the clinker into a superfine powder.

الحصول على السعر

Cement Wikipedia

A cement is a binder, a substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces is the most widely used material in existence and is only behind water as ...

الحصول على السعر

Manufacturing Process of Portland Cement TCL Blog

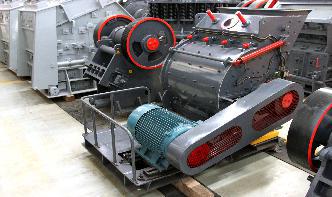

Aug 26, 2014· Now that we have explained what cement is and how it works, we can begin to move into the processes and machinery involved in the creation of cement. Production of Portland cement begins at the Mayo Quarry where the limestone material is excavated, crushed and transported as slurry to the Claxton Bay plant, where the cement manufacturing process is completed.

الحصول على السعر

Gypsum an overview | ScienceDirect Topics

The former is called gypsum fiber board and the latter particle board. Gypsum fiber boards are made by mixing gypsum with the reinforcing fiber in a relatively dry or slightly moist condition. Not much moisture can be added to the gypsum early in the process due to rapid setting of gypsum.

الحصول على السعر

The Cement Manufacturing Process | Process Systems ...

Aug 15, 2017· The Cement Manufacturing Process Cement is a finely ground powder which, when mixed with water, forms a hardening paste of calcium silicate hydrates and calcium aluminate hydrates. Cement is used in mortar (to bind together bricks or stones) and concrete (bulk rocklike building material made from cement, aggregate, sand, and water).

الحصول على السعر

Cement Production Process SlideShare

Sep 17, 2015· Cement Production Process. The Electrostatic Precipitators are used in cement plants particularly for removal of dust from the exit gases of cement kilns and from the exhaust air discharged by dryers, combined grinding and drying plants, finishing mills and raw mills through water injection. 08 Kiln A kiln is the heart of any cement plant.

الحصول على السعر

What is the manufacturing process of cement? Quora

Aug 15, 2017· Hi, Following three distinct operations are involved in the manufacturing of normal setting or Portland ordinary cement: 1. Mixing of raw materials 2. Burning 3. Grinding MIXING OF RAW MATERIALS The raw materials such as limestone or chalk and sha...

الحصول على السعر

Manufacturing Process – Continental Cement

Cement is made from common materials such as limestone, clay, silica, and iron ore that are blended together. Click on the circles above and tour Continental Cement's Hannibal plant to view the cement making process.

الحصول على السعر

Cement Manufacturing Technology Course

The course content will be suitable for a wide range of personnel within a cement manufacturing company including junior/middle management, technicians, production and control room staff, etc and also for others who wish to gain a comprehensive understanding of the complete cement manufacturing process.

الحصول على السعر

Manufacturing process | Lafarge in United Arab Emirates ...

From the limestone quarry to the delivery of the end product, follow every step in the cement manufacturing process. Step 1: Extraction of raw materials The raw materials needed to produce cement (calcium carbonate, silica, alumina and iron ore) are generally extracted from limestone rock, chalk, clayey schist or clay.

الحصول على السعر

FGD Gypsum Use in Cement

Gypsum Gypsum Added to Control Setting Set Time Increases as Gyp Increases Various Cement and Masonry Products Have a Range of SO 3 Content SO 3 at % is a Typical Value

الحصول على السعر

8 Main Cement Ingredients Their Functions Civil ...

Almost every construction work requires cement. Therefore, the composition of cement is a matter of great interest to engineers. For understanding cement composition, one must know the functionality of Cement ingredients. By altering the amount of an ingredient during cement production, one can achieve the desired cement quality. Ingredients of ...

الحصول على السعر

Cement Manufacturing Process Civil Engineering Blog

Aug 27, 2015· Cement Manufacturing Process. The entire operation of the plant is controlled centrally in a single control room and the plant employs minimum of manpower. The modern plants have also taken adequate care to prevent the environmental pollution and dust nuisance to its surrounding areas. The cement mills have electrostatic precipitators (ESP)...

الحصول على السعر

The role of gypsum in the production of cement?

Thus, the reaction of C3A with water is very rapid and is regulated by adding gypsum during production. Gypsum (composed of crystallized calcium sulfate (CaSO4) is added to Portland cement to ...

الحصول على السعر

How Portland Cement is Made? Manufacturing Process of ...

Manufacturing Portland Cement. The clinker is then ground to produce portland cement. Gypsum is added during the grinding process to control the set rate of the cement. Slag and fly ash can also be added to control other properties of the final product. Both .

الحصول على السعر

Raw Materials for Cement Manufacture

Raw materials for cement manufacture. ... (the wet process) or in dry form (the dry process). The addition of water facilitates grinding. However, the water must then be removed by evaporation as the first step in the burning process, which requires additional energy. The wet process, which was once standard, has now been rendered obsolete ...

الحصول على السعر

So3 / cement Page 1 of 3 International Cement Review

Re: So3 / cement. Dear Mr. Raja . thank you very much for help and please the cement type is SRC with max SO3 % . and my problem with high S03 limit in clinker 2 % . that`s give rise to complication gypsum addition in cement i had another question . can i grind the high So3 clinker with out gypsum .

الحصول على السعر

Cement Making Process CRH Cement

Quality You Can Trust. Cement and cementitious products are shipped to our extensive network of terminals for distribution in bulk or bagged form. Our customers include readymix concrete producers; building contractors; manufacturers of brick, blocks, paving stones, pipes; building material dealers, and the mining industry. Our ISO 9001...

الحصول على السعر

Cement Manufacturing Process Civil Engineering

Stage of Cement Manufacture. There are six main stages of cement manufacturing process. The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite. The ore rocks are quarried and crushed to smaller pieces of about 6 inches.

الحصول على السعر

Why Is Gypsum Added to Cement? | Hunker

The terms cement and concrete are used interchangeably, although cement is actually an ingredient of concrete. Gypsum is often added to cement and concrete to slow down the drying time. Cement dries quickly and retarding that process allows workers to pour the .

الحصول على السعر

Clinker (cement) Wikipedia

Portland cement clinker is ground to a fine powder and used as the binder in many cement products. A little gypsum is sometimes added. It may also be combined with other active ingredients or chemical admixtures to produce other types of cement including: ground granulated blast furnace slag cement; pozzolana cement; silica fume cement; Clinker, if stored in dry conditions, can be kept for several .

الحصول على السعر

Cement Manufacturing Process – NPC

Cement Manufacturing Process Cement is the basic ingredient of construction and the most widely used construction material. It is a very critical ingredient, because only cement has the ability of enhancing viscosity of concrete which in returns provides the better locking of .

الحصول على السعر

Cement, lime and gypsum manufacturing processes have in ...

cement process or lime kiln. Under 677°C (1250°F), an insitu can be used for an oxygen (O 2)only measurement. In many dry cement kilns, only a watercooled probe can survive the high temperatures for extended operation. Some customers install a type of deflector pipe to the process and mount the analyzer directly onto it.

الحصول على السعر