manufacturing process coarse and fine aggregate

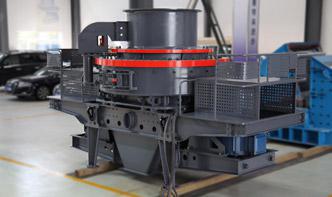

Guangdong Changda NFLG Fine Aggregate Production Line ...

Highlights of the Equipment: This new production technology realizes the following procedures in the aggregate production process to meet the high demand of Hong Kong–Zhuhai–Macau Bridge: Aggregate crushing, shaping, screening, surface stone powder removal, stone powder content control, fine aggregate screening, fine aggregate proportion adjustment, stone powder collection, and refining ...

الحصول على السعر

Aggregates

Coarse aggregates are any particles greater than inch, but generally range between 3/8 and inches in diameter. Gravels constitute the majority of coarse aggregate used in concrete with crushed stone making up most of the remainder. Natural gravel and sand are usually dug or dredged from a pit, river, lake, or seabed.

الحصول على السعر

Lecture 4. Aggregates Aalto

Currently, only the use of coarse aggregate derived from construction or demolition waste is recommended for use in new concrete construction. • The characteristic of recycled aggregates could be different by its parent concrete because the

الحصول على السعر

manufacturing process of coarse aggregate

Lightweight Aggregate Manufacturing US EPA. Lightweight Aggregate Manufacturing Process Description1,2 Lightweight aggregate is a type of coarse aggregate that is used in the production of lightweight concrete products such as concrete block, structural concrete, and pavement.

الحصول على السعر

process of making aggregate

process to making coarse aggregates natureslimsecretscoza. THE NEED FOR STANDARDIZATION OF, process to making coarse aggregates,THE NEED FOR STANDARDIZATION OF AGGREGATES FOR CONCRETE PRODUCTION IN ETHIOPIAN CONSTRUCTION INDUSTRY Abebe Dinku Civil Engineering Department Addis Ababa University, Ethiopia [email protected], Fine and coarse aggregates make .

الحصول على السعر

types of aggregate manufacture process

New type of crushed, of their crushed sand want to emphasize that it is different from the material that is cogenerated in the coarse aggregate production process. Construction aggregate Wikipedia. Construction aggregate,, types of coarse and fine aggregate designed for, system for the manufacturing process to ensure an aggregate that .

الحصول على السعر

Process Of Making Coarse Aggregate

Process Of Making Coarse Aggregate Fine aggregates generally consist of natural sand or crushed stone with most particles the majority of coarse aggregate used in concrete with crushed stone making up If necessary, a benefaction process such as jigging or heavy media. Jaw Crusher.

الحصول على السعر

GRADATION OF AGGREGATE FOR CONCRETE BLOCK

the weight per cubic foot of various mixtures, of the fine and coarse aggregates, can be determined. The blend yielding the highest unit weight will serve as a starting blend for a block mix. This method is usable only with aggregates in which the fine and coarse sizes .

الحصول على السعر

The Process Of Making Coarse Agreggate

process of making coarse aggregate pdf fiberglassrod sieve analysis of fine and coarse aggregates Method A Coarse, Fine, or a Combination of Coarse and Fine . describe the manufacturing process for aggregate. describe the manufacturing process for . The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. ...

الحصول على السعر

WHAT ARE THE PROPERTIES OF AGGREGATES FOR CONCRETE ...

Oct 01, 2016· The specific surface area of the fine aggregate is very much more than that of coarse aggregate. Also read: How to Calculate Total Surface Index of Aggregate. 11. Deleterious Materials. Aggregates should not contain any harmful material in such a quantity so as to affect the strength and durability of the concrete.

الحصول على السعر

Comparison of natural and manufactured fine aggregates in ...

Request PDF on ResearchGate | Comparison of natural and manufactured fine aggregates in cement mortars | The performance of cement mortars using manufactured fine aggregates produced by cone ...

الحصول على السعر

HOW TO CLASSIFY AGGREGATES ACCORDING TO SIZE ...

Jul 07, 2014· According to size the aggregates are classified as: Fine Aggregate Coarse Aggregate All in Aggregate Fine Aggregate It is the aggregate most of which passes mm IS sieve and contains only so much coarser as is permitted by specification. According to source fine aggregate may be described as: Natural Sand– it is the aggregate [.]

الحصول على السعر

What is the difference between fine aggregate and coarse ...

Fine aggregate and coarse aggregate differ in various aspect: FA Fine aggregate CA Coarse aggregate 1. FA comes in size ranging from mm to 90 micron, whereas CA ranges from 80 mm to 10 mm. 2. In concrete, FA is responsible for filling up ...

الحصول على السعر

Coarse Aggregates

Order building materials from our online store. Get wholesale market rates from manufacturers and suppliers directly at

الحصول على السعر

cement fine aggregate grinding mill

Aggregates making plant for coarse and fine aggregate . Common aggregate can be classified into coarse aggregate and fine aggregate. The aggregates which particle size is larger than is called coarse aggregate, including gravel, crushed stone, slag, etc. ... Chemical Reactions during Cement Manufacturing Process.

الحصول على السعر