bismuth ore leaching

GoldBismuthCopper mineralisation in the Tennant Creek ...

GOLDBISMUTHCOPPER MINERALISATION IN THE TENNANT CREEK DISTRICT, NORTHERN TERRITORY, AUSTRALIA. by Ross R. Large Thesis submitted for the degree of Doctor of Philosophy, Geology Department, University of New England, Armidale, New South Wales. January, 1974.

الحصول على السعر

Thiosulfate leaching of silver, gold and bismuth from a ...

Apr 01, 2005· The selective leaching of a bismuth from the lead concentrate (Atacocha, Peru) by using of sodium thiosulfate and mechanical activation as the pretreatment step was examined as the last example. It is possible to achieve more than 90% recovery of a bismuth in leachate even in three minutes for mechanically activated samples.

الحصول على السعر

Recovery of Copper from Reverberatory Copper Slag and ...

The copper slag contains a high content of silica and iron. The solution final pH is the most important factor affecting the removal of iron and silica from the leach solution and the overall metal recovery. Fe removal from the leaching of copper slag is done by the formation of a metal hydroxide.

الحصول على السعر

USA1 Method of Extracting Te and Bismuth ...

A method of extracting Te and bismuth oxide and recovering byproduct comprises: leaching raw materials with a Te content of ≧% by utilizing a leaching system containing H 2 SO 4, Cl −, Br −, NH 4 + and NaClO 3, reducing leach solution with SO 2 gas by precipitation method after separating impurities from it, washing with concentrated hydrochloric acid to obtain tellurium precipitation (18), purifying to .

الحصول على السعر

Rebellious Ores: Sulfides, Selenides and Tellurides

It is extremely important when treating high sulfide ores with cyanide to keep a sufficient protective base in the solution. Many sulfide minerals also contain things like copper or antimony that can react with the cyanide, preventing the cyanide from leaching out the gold and silver.

الحصول على السعر

ASSESSING A TWOSTAGE HEAP LEACHING PROCESS FOR .

leaching of ore or concentrate using the low capital and operating costs of heap leaching but with the advantage of operating at a higher temperature for faster reaction kinetics (Petersen and Dixon, 2002).

الحصول على السعر

processing bismuth from ore Mine Equipments

Bismuth Production Element Bismuth, Bi, Poor Metal Formerly bismuth was extracted principally from native ores by the process of liquation. The ore was heated in inclined cylindrical furnaces and the molten ...

الحصول على السعر

The Republic of Kazakhstan

At the cyanide leaching of preliminary oxidized sulfide ores, the process of gold solution is expressed with the equation: 4 А u + 8NaCN + 2H 2 O + O 2 = 4Na[Au(CN) 2 ] + 4NaOH. As a result of side reactions, the part of active groups of sorbent is occupied with anions of admixtures that reduces the sorbent capacity with regard to noble metals.

الحصول على السعر

bio leaching SlideShare

Jan 15, 2015· bio leaching 1. Bio leaching Group members Mehwish nazeer, Kanza saleem, Nazish mehmood javaid 2. Introduction Bioleaching is the simple and effective technology for metal extraction from low grade ores and mineral concentrate by the use of micro organisms. Commonly used microorganisms are: Mesophiles Moderately thermophilic bacteria extremophiles

الحصول على السعر

Barrick Thiosulfate Leaching of Double Refractory Ore

the Leaching Team to optimize the thiosulfate leaching process for double refractory ores. In addition, the Leaching Team analyzed the thiosulfate leaching process compared to the traditional cyanide process. They found that the profit of the thiosulfate leaching process was similar to that of the traditional cyanide method.

الحصول على السعر

C22B 30 Obtaining antimony, arsenic or bismuth Patents ...

CNA 从锑矿中浸出锑的方法 Leaching of antimony from antimony ore ... 联产硫酸锰的方法 The method of bismuth sulfide ore and manganese ore roasting interaction and ...

الحصول على السعر

Dissolution Kinetics and Leaching of Rutile Ore in ...

Leaching time (min) Fraction of rutile ore dissolved HCl HCl HCl HCl Fig. 2. Effect of HCl concentration on the dissolution of rutile ore at 550C. From Fig. 2, it is evident that the leachant has a significant effect on the leaching of the rutile ore. However, the fraction of the ore dissolved was moderate.

الحصول على السعر

Mineral Processing Bismuth

World reserves of bismuth are usually based on bismuth content of lead resources because bismuth production is most often a byproduct of processing lead ores; in China bismuth production is a byproduct of tungsten and other metal ore processing.

الحصول على السعر

A New Process of Fluosilicic Acid Leaching for Recovering ...

Chlorine selective leaching bismuth from the low grade bismuth sulphide ore[J]. China bismuth information

الحصول على السعر

NICO COBALTGOLDBISMUTHCOPPER PROJECT Technical .

mineralization in Iron Ore Copper Gold type geological setting Geological Survey of Canada 1994 airborne geophysical survey identified large intense anomalies coincident with mineralization Drilling between 1994 2006 (291 holes, totaling 58,000 metres) delineated deposit other mineral showings

الحصول على السعر

C22B 30 Obtaining antimony, arsenic or bismuth Patents ...

CNB Process for recycling bismuth concentrate from tungsten ore magnetic ... CNA Arsenicalkali separation method for leaching agent .

الحصول على السعر

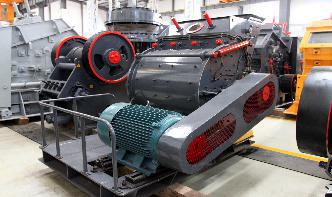

Heap Leaching Mining Techniques, Metals Mining, Copper ...

Heap leaching is an industrial mining method to dig out precious metals and copper compounds from ore. Process of heap leaching. The mined ore is crushed into tiny chunks and heaped on an impermeable plastic and/or clay lined leach pad where it may be irrigated with a leach .

الحصول على السعر

How to Make Bismuth Crystals: 3 Steps (with Pictures)

The bismuth crystals can be snapped out of the container after the bismuth is completely solid, or they whole shape can be saved. Crystals should form in the other container as well. If the crystals are not to your liking, the bismuth can be remelted and the process can be .

الحصول على السعر

Bismuth Ore BG FFXI Wiki

Description: Dizzying numbers of veins containing the mineral bismuth crisscross the interior of this ore. Image: Type: Item Flags: Obtainable from Goblin Box

الحصول على السعر

PRESSURE LEACHING

2) The increase in penalty elements in some ore bodies – the principal penalty element being found today is arsenic which is fixed through pressure oxidation, but other elements are sometimes found, depending on the ore body, including bismuth, etc. There are two principal copper concentrate pressure leaching

الحصول على السعر