how to calculate charge volume in ball or rod mill mining

ITP Mining: Energy and Environmental Profile of the ...

Energy and Environmental Profile of the Mining Industry Beneficiation Methods Potash (rock) The ore is drycrushed by rod and ball mills to free the KCL (potassium chloride, or potash) and put into a brine similar to salt water. It is then ground into distinct particles of

الحصول على السعر

.:. Mill Critical Speed Determination

Mill Critical Speed Determination. The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell's inside surface. This is the rotational speed where balls will not fall away from the mill's shell.

الحصول على السعر

What is Bitcoin Mining and is it Still Profitable in 2019 ...

Cloud mining means that you do not buy a physical mining rig but rather rent computing power from a mining company and get paid according to how much mining power you own. At first, this sounds like a really good idea, since you don't have to go through all of the hassle of buying expensive equipment, storing it, cooling it, and monitoring it.

الحصول على السعر

Ball Milling University of Massachusetts Boston

Planetary Ball Mill PM 400 Feed material: soft, hard, brittle, fibrous (dry or wet); Material feed size: < 10 mm; Final fineness < 1 µm; No. of grinding stations: 4 / 2

الحصول على السعر

About the Mine and Mill Equipment Cost Calculator | CostMine

A quick look at our "How to Use the Cost Calculator" discussion will show you how easily this can be accomplished. Screen samples are shown here as well. Further details about the equipment specifications and cost data in the Cost Calculator are listed under "Cost Parameters and Definitions". Who Uses the Mine Mill Equipment Cost Calculator?

الحصول على السعر

Ball Milling University of Massachusetts Boston

The 12 Principles of Green Chemistry Prevention of waste Atom Economy Less Hazardous Chemical Syntheses Design Safer Chemicals Safer Solvents and Auxiliaries for ...

الحصول على السعر

Theoretical Metal Weight Calculation Formula (30 Types of ...

If you're working in the metalworking industry, even you're engineers, you will try to find one calculator to help you calculate the weight of various metals and steels including ms plate, gi sheet, structural steel, ms angle, mild steel, steel bar, square tube, angle, aluminum etc.. Theoretical Metal Weight Calculator. Below is the calculator for you to calculate the weight of various metals.

الحصول على السعر

how to calculate batch volume in ball mill – Grinding Mill ...

calculates the grinding charge of a ball mill | Mining ... calculates the grinding charge of a ball mill How to Calculate Charge Volume in Ball or Rod Mill. a 180 cm dia x 180 cm long batch type ball mill with Duralox ... » Learn More

الحصول على السعر

Mineral processing Wikipedia

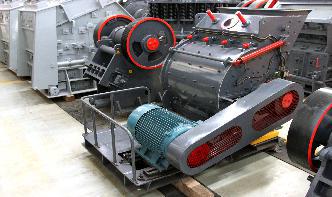

The primarily used equipment in crushing arejaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant. Crushing is a dry process whereas grinding is generally performed wet and hence is more energy ...

الحصول على السعر

Fine grinding in a horizontal ball mill ScienceDirect

For all of the tests, the mill was operated at 70 revolutions per minute (RPM) with a ball loading of 20% (by volume). The amount of ore used for each test was the mass equivalent to 700 mL ( kg). These parameters were the same as those used by Bond (1961) and .

الحصول على السعر

Principles of bearing selection and application | SKF

Single row deep groove ball bearings . Stainless steel deep groove ball bearings . Single row deep groove ball bearings with filling slots . Double row deep groove ball bearings . Bearing data . Loads . Temperature limits . Permissible speed . Designation system . Insert bearings (Ybearings) Angular contact ball bearings . Single row angular contact ball bearings

الحصول على السعر

SmallScale Tests to Characterise Ore Grindibility

The Bond rod mill work index is used to calculate the power requirement at intermediate size, from to about 1mm. The test has been mainly used for the design of rod mills or primary ball mills, but it can also be used along with the other Bond tests (BWI and cWI) for SAG mill design using semiempirical relationship [6]. BOND LOWENERGY IMpACT TEST

الحصول على السعر

Mill lining solutions PolyMet mill linings

system mass, it is often possible to increase mill charge volume without risk of mill structural overload. Feed end head plates Balance the wear life It can be a challenge to minimize downtime by reaching a balanced wear life between different mill lining components, such as head plates and lifters or inner and outer rings of liners.

الحصول على السعر

The influence of mill speed and pulp density on the ...

volume of the pulp in the mill is then calculated using the mill discharge density (before dilution) obtained during the sampling. The ball charge, and hence the volume of the voids between the balls in the mill, is known and we are then able to calculate the factor 'volume pulp/volume voids .

الحصول على السعر

volume charging formula in ball mill – Grinding Mill China

Calculate Ball Mill Charge Calculate Ball Mill Charge; ball mills ball charge, how to calculate charge volume in how to calculate charge volume in ball or rod mill, ball mills ball charge » Learn More. calculate capacity of a grinding mill Grinding Mill China

الحصول على السعر

Advanced Physics Homework Help Forum | Physics Forums

Oct 12, 2019· Receive advanced physics homework help via mentors. This is usually calculus based upper undergraduate and graduate level. Please use the .

الحصول على السعر

Nut Weight Chart Portland Bolt

Portland Bolt provides anchor bolts and nonstandard construction fasteners directly to contractors, steel fabricators, and other companies worldwide.

الحصول على السعر

Sciencing: Making Science Fun for All Ages

Whether you have questions about the universe or a molecule compound or what biome you live in, is your goto source for all things science.

الحصول على السعر

A NEW MACHINING COST CALCULATOR (MC2

must be calculated. To calculate the distance of the full feed rate portion of the move, twice the distance to accelerate to the feed rate is subtracted from the total move distance. The result is the distance over which the tool will travel at the commanded feed rate. Then, .

الحصول على السعر

SAG Mill Testing Test Procedures to Characterize Ore ...

rod mill grindability tests. As discussed earlier in this paper, it is important in this case to match the reduction size of the test to that desired from the industrial mill. As such, primary ball mills should be designed with the rod mill work index, and singlestage ball mills should be with both the rod mill and ball mill .

الحصول على السعر

Grinding in Ball Mills: Modeling and Process Control

The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material (feeders), and the system for discharging the output product. The size of a mill is usually characterized by the ratio "length to diameter" and this ratio most frequently varies from to

الحصول على السعر

Ball Mill Medias Tencan

Lab Sand Mill. Lab Rod Mill. Lab Rapid Ball Mill. Lab Glove Box / Operation Box. CONTACT. Tel: . Fax: . Mobile: . Email1: mills Email2: service Ball Mill Medias. Iron Core PU Mill Ball. Zirconia Mill Ball. Tungsten Carbide Mill Ball. Alumina Mill Ball. Agate Mill ...

الحصول على السعر

Dry ball mill rpm calculation

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell's inside surface and no balls will fall from its position onto the shell. The imagery below helps explain what goes on inside a mill as speed varies. ... Calculate and Select Ball Mill Ball .

الحصول على السعر