cement mill process identification

Grinding Media Grinding Balls | Union Process, Inc.

Union Process is the source for the most uptodate information on grinding balls and other media. Click the link above to view a detailed sheet, outlining factors to consider when selecting grinding media, along with specifications on the most common types of media.

الحصول على السعر

Welcome to Skyway Cement Company

S kyway Cement Company produces Slag cement, which is a valued construction material due to its superior performance and environmental qualities. Skyway's manufacturing facility is located in southeast Chicago near the Skyway Bridge. Skyway Cement is used in a wide variety of commercial and architectural concrete construction applications which include castin place, precast, bridges, roads ...

الحصول على السعر

MEC

No.(1) Steel Rolling Mill (Kyauk Swae Kyoe) No.(2) Steel Mill And Fabrication Shop (Myaungdagar) No.(3) Steel Mill (Ywama) Ship Breaking Yard (Thilawa) No.(1) 900 TPD Process Cement Plant (Myainggalay) No.(2) 4,000 TPD Process Cement Plant (Myaingglay) and Paper Making Machine (Myaingglay) Sugar Mill (Kanbalu) Sugar Mill (Kanhla) Sugar Mill (Du ...

الحصول على السعر

Discover

FL delivers sustainable productivity to the global mining and cement industries. As the marketleading supplier of engineering, equipment and service solutions, FL improves performance, drives down costs, and reduces the environmental impact of operations. Present in more than 50 countries and headquartered in Copenhagen, Denmark ...

الحصول على السعر

Cement plant mill energy saving measures

In the cement plant, grinding is an important process of cement production, and also the main power consumption process of cement production. The following measures from the aspects of process, electrical, equipment, operation, etc., reduce the mechanical and electrical consumption of grinding.

الحصول على السعر

Cement, How It Is Produced Mine

Cement, or Portland cement, is defined as "a hydraulic cement, obtained by burning a mixture of lime and clay to form a clinker, then pulverizing the clinker into powder. The greenish gray powder is composed primarily of calcium silicates, calcium aluminates, and calcium ferrites.

الحصول على السعر

Chemical, Mineralogical, and Morphological Properties of ...

Steel slag is a byproduct of the steelmaking and steel refining processes. This paper provides an overview of the different types of steel slag that are generated from basicoxygenfurnace (BOF) steelmaking, electricarcfurnace (EAF) steelmaking, and ladlefurnace steel refining processes. The mineralogical and morphological properties of BOF and electricarcfurnaceladle [EAF(L)] slag ...

الحصول على السعر

Grinding in Ball Mills: Modeling and Process Control

the milling process takes place during rotation as a result of the transfer of kinetic energy of the moving grinding media into the grinding product. The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material (feeders), and .

الحصول على السعر

MILSTD792 F MANUFACTURING PROCESS IDENTIFICATION

MILSTD792F, DEPARTMENT OF DEFENSE MANUFACTURING PROCESS STANDARD: IDENTIFICATION MARKING REQUIREMENTS FOR SPECIAL PURPOSE COMPONENTS (19 MAY 2006)., The purpose of this standard is to provide general requirements for the marking of raw materials, products, and components.

الحصول على السعر

Milling Tools | Schlumberger

Pilot mills are suitable for milling sections of tubular junk and can be used as a dress mill for installing casing patches or milling liner hangers and other downhole tools with a throughbore. These milling tools are available from 3 1/4 to 17 in, with fishing necks from 3 1/8 to 8 in. Millmaster section mills

الحصول على السعر

St. Marys Cement

Cement PRODUCTS AND SERVICES. SUCCESS STORIES. Global Presence. Explore an interactive map showing all of our office and production facilities in communities like this one all around the world. NEWS HOW YOU CAN REACH US ...

الحصول على السعر

Energy Consumption Benchmark Guide: Cement Clinker .

Cement Association of Canada (formerly known as the Portland Cement Association of Canada). The Association captured much of the data from and Canadian Portland Cement Industry: Plant Information Summary for 1998, the last year for which data are available. 1 Energy Consumption Benchmark Guide: Cement Clinker Production

الحصول على السعر

DD Form 11722, Application for Identification Card/DEERS ...

Please wait... If this message is not eventually replaced by the proper contents of the document, your PDF viewer may not be able to display this type of document.

الحصول على السعر

Cement Mill Process Engineer

Cement Mill Process Engineer Holcim Indonesia Cilacap Plant. Jan 2013 – Present 6 years 10 months. Process Optimalization Process Optimalization. Production engineer PT Sarana Agra Gemilang Semen Kupang. Aug 2010 – Jan 2013 2 years 6 months. Memastikan produksi berjalan continu Memastikan produksi berjalan continu.

الحصول على السعر

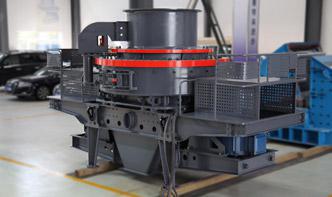

cement plant equipments manufacturer and suppliers of ...

Ashoka's cement plant unit has continued focused on objectives of product improvement and quality. In our entire turnkey cement plant equipments and machinery, we supply a complete assembly consisting of different machines and equipment, which facilitate the plant to execute efficiently and manufacture a betterquality completed product as per the international quality standards.

الحصول على السعر

Risk Assessment and Control Measures for Cold Rolling Mill ...

Risk Assessment and Control Measures for Cold Rolling Mill in Steel Industry ... identification, assessment, elimination and/ or the control of hazards ... This process is called risk assessment, and it is the evaluation of hazards to determine their potential to cause an accident. When most people hear the term risk assessment, they ...

الحصول على السعر

cement mill process flow separate grind vertical mill

cement grinding in vertical roller mill process. vertical mill for separate grinding process in cement Vertical roller mill for cement grinding In the cement grinding process, grinding system using the tube mill is widely In a vertical coal mill, drying, grinding, and separating/classifying of ground

الحصول على السعر

How Cement Is Made

Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

الحصول على السعر

PERMITTEE: Ash Grove Cement Company

Ash Grove Cement Company Permit #: 0075AOPR16 AFIN: 9 The raw material building from the decommissioned long dry kiln process has been converted to store coal, petroleum coke, limestone, and gypsum. A new coal silo and coal mill has been constructed for the PH/PC kiln system. The equipment designated for handling, storing, and

الحصول على السعر

Cement Hazards and Controls Health Risks and Precautions ...

Cement dust released during bag dumping or concrete cutting can also irritate the skin. Moisture from sweat or wet clothing reacts with the cement dust to form a caustic solution. Allergic skin reaction. Some workers become allergic to the hexavalent chromium in cement.

الحصول على السعر

Portland Cement Dust Health and Safety Executive

exposed to the raw materials of cement production, which include limestone, chalk, clay and shale, to clinker, as well as to Portland cement dust. The exact nature of the dust exposures experienced by cement plant workers has not been characterised in any of the studies. Consequently, one cannot exclude

الحصول على السعر