processing stages of iron ore

Production of High Grade Iron Ore Concentrates Using Flota.

The Brazilian iron ore industry has led the world in adopting column flotation technology for reducing the silica content of iron pellets[5]. Several companies have installed, or are in the process of insta lling column cells into their process flowsheets.

الحصول على السعر

What are the stages of manufacturing pig iron, wrought ...

Oct 13, 2018· Having spent 40+ years as a metallurgical engineer and steelmaker, I am pleased to answer this question. Coke Oven – Blast Furnace – Basic Oxygen Furnace Steelmaking, called an "Integrated Steelmaking Plant" 98% of all iron ore mined, mostly Fe2O3...

الحصول على السعر

Processing Citic Pacific Mining

The ball mills, the second stage grinding equipment, are in diameter and long, each with two 7800 kW motors. 52 magnetic separators are used in each of the processing lines. Two concentrate thickeners, each 45m in diameter and four tails thickeners each 90m in diameter. Four dewatering buildings, each containing seven press filters.

الحصول على السعر

Kiruna Iron Ore Mine Mining Technology | Mining News and ...

The ore will then be skiphoisted approximately vertically in two stages to the processing plant. Mining will be carried out in ten production areas. Each area will be equipped with an access road, ventilation and media systems, and multiple ore passes and rock chutes.

الحصول على السعر

FROM DEPOSIT TO MINE FROM MINE TO MINING VALUE .

FROM DEPOSIT TO MINE FROM MINE TO MINING VALUE CHAINS Neale Baartjes ... chromium and vanadium bearing titanium iron ore formations ... Mining Processing Refining Fabrication Stage 1 Stage 2 Stage 3 Stage 4. SOUTH AFRICAN JARGON Medium to High Medium to High The action of

الحصول على السعر

A Look at the Process of Pelletizing Iron Ore for Steel ...

Pelletizing, or balling, is a key part of efficiently and sustainably producing steel from iron ore fines of varying sources.

الحصول على السعر

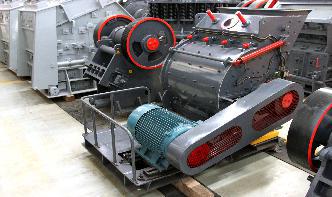

2 sizer stages iron ore processing plant

2 size stages iron ore processing plant. Pelletizing Wikipedia 2 size stages iron ore processing plant,Pelletizing is the process of compressing or molding a material into the shape of a wide range of different materials are pelletized including chemicals, Get Price.

الحصول على السعر

iron ore processing stages

Iron Ore Processing for the Blast Furnace. processing facility located on the Mesabi Iron Range of Minnesota. Creating steel from lowgrade iron ore requires a long process of mining, crushing,. Live Chat

الحصول على السعر

Mining Global Mining News, Magazine and Website

Mining Global provides latest mining news, a monthly mining magazine and a mining website for companies, associations and mining executives globally.

الحصول على السعر

Steelmaking and Refining | Introduction to Chemistry

Steelmaking Overview. Steelmaking is the second step in producing steel from iron ore. In this stage, impurities such as sulfur, phosphorus, and excess carbon are removed from the raw iron, and alloying elements such as manganese, nickel, chromium, and vanadium are added to .

الحصول على السعر

Aluminium production process

BAUXITE MINING. The aluminium production process starts with the mining of bauxites, an aluminium rich mineral in in the form of aluminium hydroxide. About 90% .

الحصول على السعر

Extraction Of Iron SlideShare

May 22, 2009· The Step by Step Process of Extracting Iron from its Ore using the Blast Furnace with details of Chemical Reactions. Question Answers based on the process of extraction of metals.

الحصول على السعر

IRON AND STEEL chemguide

Loss of landscape due to mining, processing and transporting the iron ore, coke and limestone. Noise and air pollution (greenhouse effect, acid rain) involved in these operations. Extracting iron from the ore. Think about: Loss of landscape due to the size of the chemical plant needed. Noise. Atmospheric pollution from the various stages of extraction.

الحصول على السعر

Ore processing – Waihi Gold

Ore processing is a 24 hour operation. Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added (2) to raise the pH of the ore.

الحصول على السعر

5 stages of extraction of iron BINQ Mining

Mar 23, 2013· 5 stages of extraction of iron – . Iron – Wikipedia, the free encyclopedia. The first stage is to produce pig iron in a blast furnace. . Ninety percent .

الحصول على السعر

Solutions Of Mineral Process

Double Stages Slurry Pump; Grinding Classification Equipment. Grinding. Grid Type Ball Mill; ... Chrome Ore Mining Process; Magnetite Separation Production Line; Gold Cip Production Line; Navigation Home . ... Iron Ore Mining Process. Antimony Mineral Processing. Chrome Ore Mining Process. Dolomite Mining Process.

الحصول على السعر

How Is Gold Extracted From Gold Ore? | Sciencing

Another process involves ground ore being passed over plates which are coated with mercury. The gold and the mercury form an amalgam, leading to the name of the process, amalgamation. Once the amalgam has formed, it is heated until the mercury gas is boiled off, leaving the gold. The mercury gas is highly toxic and must be handled carefully.

الحصول على السعر

EXTRACTION OF IRON EXTRACTION OF IRON FROM HAEMATITE

The process of the extraction of iron is carried out by the following steps: Concentration of ore Calcination or Roasting of ore Reduction of ore : Concentration of ore: In this metallurgical operation, the ore is concentrated by removing impurities like soil etc. .

الحصول على السعر