catia design of ball mill

How can you design of ball mill Answers

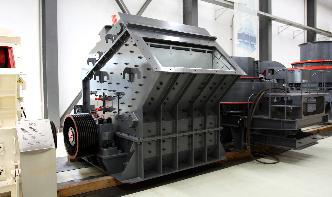

The ball mill is widely applied in mineral classification, cement, fireproof materials, glass, pottery, chemical industry and so on. The ball mill can grind all kinds of rocks and grinding materials.

الحصول على السعر

Grinding in Ball Mills: Modeling and Process Control

The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material (feeders), and the system for discharging the output product. The size of a mill is usually characterized by the ratio "length to diameter" and this ratio most frequently varies from to

الحصول على السعر

THE OPTIMAL BALL DIAMETER IN A MILL Strona główna

The optimal ball diameter in a mill 335 By the method of the least squares, it was possible to determine the numerical values of parameters K and n in Eq. 1, with a very high degree of correlation r, so that they, for the conditions of our experiment, would be as follows: quartz:, r=, (11) copper ore:, r=

الحصول على السعر

Ball Mill Manufacturers, Suppliers Exporters Delhi

Published on Jun 21, 2014. Ball Mill India This machine is a skeleton pattern ball mill with horizontal cylindrical turning gear, drive by outer gear and two hoppers. The material goes to the first hopper after the spiraling by the quill shaft from the feeding equipment.

الحصول على السعر

Ball mil design calculation? | Yahoo Answers

Mar 31, 2008· The power (in kW) required to turn a ball mill is approximated by: P = d () m n where d is the internal diameter in metres, j is the fraction of the mill volume occupied by media, m is the total mass of media in the mill, in tonnes, and n is the mill speed, rpm.

الحصول على السعر

Hami Khoshdast – CAD Konstrukteur – Produktentwicklung ...

Sehen Sie sich das Profil von Hami Khoshdast auf LinkedIn an, dem weltweit größten beruflichen Netzwerk. 7 Jobs sind im Profil von Hami Khoshdast aufgelistet. Sehen Sie sich auf LinkedIn das vollständige Profil an. Erfahren Sie mehr über die Kontakte von Hami Khoshdast und über Jobs bei ähnlichen Unternehmen.

الحصول على السعر

Mill (grinding) Wikipedia

Ball mill. A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls. Ball mills normally operate with an approximate ball charge of 30%.

الحصول على السعر

How to Make a Ball Mill: 12 Steps (with Pictures) wikiHow

Mar 29, 2019· They are similar to rock tumblers in that the instrument is a rotating container filled with heavy balls to grind the substance into powder. Ceramic material, crystalline compounds, and even some metals can be ground up using a ball mill. Using a motor, container, belt, caster wheels, and some basic building supplies, you can make your own ball mill.

الحصول على السعر

DESIGN OF A BLADELESS WIND TURBINE

Fig shows the 2D draft of disc, washers, shaft and ball bearing assembly modeled in CATIA V5 R20. Each disc is separated by mm thick washer. Eleven discs, twelve washers and two ball bearings are mounted on a 76mm long shaft. Fig CATIA 2D Draft assembly of .

الحصول على السعر

(PDF) Selection and design of mill liners ResearchGate

An overview of the selection and design of mill liners was published by Powell et al (2006), providing a reference source on mill liners, however no comprehensive technical manual or training is ...

الحصول على السعر

The Dynamics Simulate Analysis of the Ball Mill with ...

The ball mill is the important equipment in the mining industry, with the development of the macroscale ball mill, and is more difficult of liner's wearing,installation and taking apart. The service life which raises a liner will prolong the production period that the ball mill, influencing an economic benefit of the concentrating mill.

الحصول على السعر

Ruby Christiyanto Technical Support Specialist, Screen ...

View Ruby Christiyanto's profile on LinkedIn, the world's largest professional community. Ruby has 4 jobs listed on their profile. See the complete profile on LinkedIn and discover Ruby's ...

الحصول على السعر

Ball End Mills | Regal Cutting Tools

The design of a two flute ball end mill allows for plenty of chip evacuation making them most effective in contouring deep pockets in molds and dies. Four or more fluted ball nose end mills have less chip evacuation due to their design but with multiple cutting edges they can produce very smooth finish by running lighter chip loads, without sacing a high rate of production.

الحصول على السعر

Solidworks car for machining and Catia. | Engineering and ...

May 26, 2012· Solidworks car for machining and Catia. As this project is about using solidCAM the final part will have not excessive detail, the finishing mill will be a 6mm ball end mill which will not machine out the finer details. The final part will be with in about 200mm x 150mm x 100mm (the size of the wax block) I have used my wheel I created...

الحصول على السعر

Manual design of SAG/ball/rod mill foundations ...

Mar 14, 2007· As an engineer who has experience using FEM for the design and assessment of SAG and ball mill foundations, I know that this approach can be timeconsuming, costly and in some cases not even a hope of being accurate if you don't have appropriate geotechnical and manufacturer information.

الحصول على السعر