how to make clinker cement

Composition of cement

Composition of cement. Manufacture of cement Portland cement is manufactured by crushing, milling and proportioning the following materials: Lime or calcium oxide, CaO: from limestone, chalk, shells, shale or calcareous rock Silica, SiO 2: from sand, old bottles, clay or argillaceous rock Alumina, Al 2 .

الحصول على السعر

Bulk cement clinker carried in conventional bulk carriers

Cement clinker is the semimanufactured material which needs to be ground into powder to make ordinary cement. It may present fewer problems than the carriage of cement. Its biggest advantage is that it does not harden when in contact with water, reducing the damage it can cause to the vessel.

الحصول على السعر

How to Make Bricks from Concrete: 8 Steps (with Pictures)

Aug 30, 2019· Step 1, Make the forms you need to use for the concrete bricks. This requires basic carpenter tools and a sheet of .75inch (19 mm) plywood along with 2 x 4inch ( x cm) by 8 feet ( m) lumber. Use 9 x 4 x inches ( x x cm) for your brick dimensions.[1] Rip the sheet of 3/4 inch plywood down to 12inch ( cm) wide x 48inch ( m) long strips. This will give you 8 .

الحصول على السعر

how to make concrete bricks and blocks

Hand mixing should be done, using shovels, on a level concrete slab or steel plate. First spread the sand out 50 to 100 mm thick. Then distribute the cement, and stone if any, evenly over the sand. Mix aggregate and cement until the colour is uniform.

الحصول على السعر

Ask the Builder: Use clinker bricks to make interesting ...

AE Ask the Builder: Use clinker bricks to make interesting structures. Sat., June 15, 2019, 1 Clinker brinks aren't uniform, so they create an interesting feature on houses and in gardens.

الحصول على السعر

Clinker and Cement Everyting for clinker and cement (in ...

Final products such as clinker or cement are subject to regular control procedures required by the usual quality specifications as laid down in applicable national or international quality standards. 38 Guidelines on coprocessing Waste Materials in Cement Production 6. 0 Requirements for coprocessing in Cement Kilns Monitoring and auditing

الحصول على السعر

Clinker substitute (slag, natural pozzolans, synthetic ...

As clinker production is the most energyintensive and CO 2emitting step of the cementmaking process, reductions in the clinker/cement ratio (through use of clinker substitutes) reduce energy use and process CO 2 possible way to reduce energy and process emissions in cement production isto blend cements with increased proportions of alternative (nonclinker) feedstocks, such as volcanic .

الحصول على السعر

How clinker forms in fbc boiler Answers

Oct 18, 2009· Slow down the stroke of the grates of the cooler.. Increase the clinker abundance and pressure in cooler.. So, you can increase the temperature by taking advantage of the hot clinker. ...

الحصول على السعر

Make Concrete Rocks for Rock Walls, Fire Pits, Walk Ways ...

Now smooth out the concrete. The easiest way to even out the concrete to remove voids and air pockets is to pat the concrete with your hands, kick The mold and shake the mold. For even better results set the mold on a vibrating table for a few minutes. The next step after the concrete has been poured and smoothed out is to wait.

الحصول على السعر

Cement, How It Is Produced Mine

Cement, or Portland cement, is defined as "a hydraulic cement, obtained by burning a mixture of lime and clay to form a clinker, then pulverizing the clinker into powder. The greenish gray powder is composed primarily of calcium silicates, calcium aluminates, and calcium ferrites.

الحصول على السعر

Is Green Cement the Future of Sustainable Construction ...

Jan 15, 2019· Finally, gypsum is mixed with clinker, forming cement. The clinker production process is highly energyintensive and releases gaseous effluents. For 1 tonne of cement produced, to 1 tonne of carbon dioxide is released. In addition to clinker production, there are other processes in cement manufacture that give off CO2.

الحصول على السعر

How concrete is made material, manufacture, making, how ...

Preparing Portland cement 1 The limestone, silica, and alumina that make up Portland cement are dry ground into a very fine powder, mixed together in predetermined proportions, preheated, and calcined (heated to a high temperature that will burn off impurities without fusing the ingredients).

الحصول على السعر

Making Concrete Change: Innovation in Lowcarbon Cement ...

Portland cement, which tends to be made up of >75 per cent Portland clinker, 31 is used in more than 98 per cent of concrete produced globally today. 32 There are good reasons for this: it is cheap, it produces a highquality concrete, it is reliable and easy to use, and the raw materials needed to produce it (limestone, chalk and marl) tend to be abundantly available and colocated. 33 Maybe most .

الحصول على السعر

Are You Mining Minerals for Cement, or for Concrete?

Various compounds can be controlled like quartz in raw meal, hot meal, free lime in clinker, clinker phases, additions in cement, limestone, GBFS or pozzolan or even clinker content in cement. Clinker phase analysis ensures consistent clinker quality, which is the key to highperformance concrete.

الحصول على السعر

Making concrete green: reinventing the world's most used ...

Mar 03, 2016· Making concrete green: reinventing the world's most used synthetic material. "Steel is often used as a reinforcing agent for this type of concrete, and is very energyintensive. Using plastic to reinforce concrete instead of steel can reduce carbon dioxide production by about 50%. However, with recycled plastic,...

الحصول على السعر

Cement some basic definitions

Clinker: Portland cement is made by grinding clinker and a little added gypsum. Clinker is a nodular material before it is ground up. The nodules can be anything from 1mm to 25mm or more in diameter. Cement: Usually taken to mean Portland Cement, but could mean any .

الحصول على السعر

Re: Raw meal to clinker ratio Page 2 of 5

A is calculated by;. A = (Tonnes coal fired * % ash of coal fired) / (tonnes of clinker produced) (NOTE: 'coal fired' above means raw coal expressed on an airdried basis. This is because fine coal from the the coal mill usually has 45% of raw meal dust contamination from .

الحصول على السعر

make of clinker proces

Portland cement clinker, However, reading an article or two is perhaps not the best way to get a clear picture of a complex process like cement production. 24/7 online; Clinker (cement) Wikipedia. In the manufacture of Portland cement, clinker occurs as lumps or nodules, usually 3 millimetres (012 in) to 25 millimetres (098 in) in diameter, .

الحصول على السعر

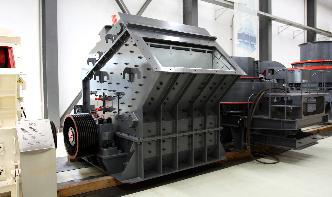

How To Make A Homemade Rock Crusher Plant Clinker

How to make a homemade rock crusher plant clinker; how to make a homemade rock crusher plant clinker. small cement processing plant . Feb 13, 2016 small cement processing plant for sale kenya concrete crusher for sale in amethod to produce biodiesel within the comfort of your own home,.

الحصول على السعر

What is the purpose of adding gypsum in cement?

During the cement manufacturing process, upon the cooling of clinker, a small amount of gypsum is introduced during the final grinding process. Gypsum is added to control the "setting of cement". If not added, the cement will set immediately after mixing of water leaving no time for concrete placing.

الحصول على السعر

Cement and Concrete An Overview ThoughtCo

Jul 24, 2018· Lime, the First Cement. Lime is made by burning, or calcining, limestone—and that's how limestone gets its name. Chemically, lime is calcium oxide (CaO) and is made by roasting calcite (CaCO 3) to drive off carbon dioxide (CO 2 ). That CO 2, a greenhouse gas, is produced in great quantities by the cement industry.

الحصول على السعر

How to Make Cement

Oct 25, 2018· How to Make Cement. The raw materials reach about 2700°F (1480°C) inside the furnace. This state facilitates some chemical and physical processes in the raw material. The resultants coming out of the furnace are small, dark gray, redhot nodules called clinker, which are 12 inches in diameter.

الحصول على السعر

Coal cement | World Coal Association

Clinker is mixed with gypsum and ground to a fine powder to make cement. Coal is used as an energy source in cement production. Large amounts of energy are required to produce cement. It takes about 200 kg of coal to produce one tonne of cement and about 300400 kg of cement is needed to produce one cubic metre of concrete.

الحصول على السعر

Technological process of cement clinker vertical grinding ...

5. firing of cement clinker After the raw meal is preheated and predecomposed in the cyclone preheater, it enters the rotary kiln for clinker firing. Carbonate is further decomposed rapidly in rotary kiln and a series of solid state reactions take place to form AC3,AFC4,SC2 and other minerals in cement clinker.

الحصول على السعر

Who Invented Cement?| Concrete Construction Magazine

Jun 11, 2019· Aspdin the elder would grind up the stone, mix it with water and clay, dry the mixture, kiln it until it was hard, and grind it up again to make his cement powder. Apparently, he discarded some of the product—the overbaked "clinkers"—because it was too hard to grind.

الحصول على السعر