about cement mill process

cement mill process flow separate grind vertical mill

cement grinding in vertical roller mill process. vertical mill for separate grinding process in cement Vertical roller mill for cement grinding In the cement grinding process, grinding system using the tube mill is widely In a vertical coal mill, drying, grinding, and separating/classifying of ground

الحصول على السعر

Cement Mill Dal Teknik

Cement and Mineral Technologies; ... Cement Mill. UNIVERSAL DRIVE BALL MILLS UDCM type mills are designed to achieve maximum grinding efficiency, low energy consumption, compact plant layout and compact mill drive design. All mill types may operate in either open or closed circuit.

الحصول على السعر

Fire and Explosion Hazards in Cement Manufacturing ...

Cement Manufacturing Process. The cement manufacturing process typically involves quarrying, drying grinding, kiln burning cooling, finish grinding, and packaging. Each of these process steps are described in the following sections. ... Bag filters used for the coal mill rank as one of the highest fire and explosion hazards in cement plants ...

الحصول على السعر

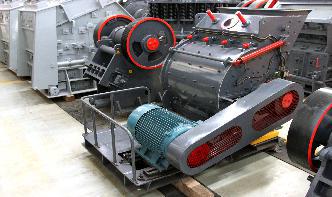

Cement Mill Machinery

Cement mill is widely used in dry or wet grinding process of all kinds of ores and other materials in such industries as cement, silicate, new building material, refractory material, fertilizer, black and nonferrous metal and glass ceramics.

الحصول على السعر

Cement Manufacturing Process Simplified Flow Chart ...

May 11, 2013· Cement manufacturing process components of a cement plant from quarry to kiln to cement mill. ... Cement Manufacturing Process Simplified Flow Chart. Posted by Johnny. May 11, 2013. ... Cement Manufacturing Process Simplified Flow Chart

الحصول على السعر

EasilyOperated Cement Mill Fote Machinery(FTM)

What is Cement Mill? Also called cement ball mill, cement mill is the key equipment that grinds the crushed materials. The cement ball mill produced by Fote adopts high chromium alloy steel or double medium quenched steel liner, which has the characteristics of high .

الحصول على السعر

Cement MillCement Mill Price Mining Machinery

The cement mill is the key equipment for regrinding cement clinker after pregrinding by system ingredients. It plays a vital role in the cement production line and cement production process. Cement mills are mainly used in cement, silicate products, new building materials, refractory materials, glass ceramics, and other production industries.

الحصول على السعر

Cement Production an overview | ScienceDirect Topics

The production of cement is either through the wet or dry process with the dry process as the preferred option because of the lower energy intensity. Cement production accounts for about 5% of total anthropogenic emissions (IFC, 2017). Cementbased structures constitute the largest surface area of all manmade structures (Odigure, 2009).

الحصول على السعر

Optimizing cement mill using techniques at Votorantim ...

Optimizing cement mill using techniques at Votorantim Cimentos in Brazil. ABB Ability™ Expert Optimizer for cement increases process stability and reduces energy costs. Share this page. Download PDF of the article.

الحصول على السعر

Cement Production Line, Cement Machinery Manufacturer ...

Cement Equipment Manufacturer. Haijian is a leading manufacturer of cement machinery in China. Since its foundation in 1970, the company has always been committed to manufacturing complete equipment of cement manufacturing plant, a large variety of host products, including cement rotary kiln, roller press, cement tube mill, vertical cement raw mill and rotary dryer, as well as much heavy ...

الحصول على السعر

Grinding in Ball Mills: Modeling and Process Control

the milling process takes place during rotation as a result of the transfer of kinetic energy of the moving grinding media into the grinding product. The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material (feeders), and .

الحصول على السعر

cement mill process plant handbook

Cement Plant OPERATIONS HANDBOOK For Dry Process Plants. CEMENT PLANT OPERATIONS HANDBOOK For Dry Process Plants .... 1930s Roller mill first applied to cement manufacture; rapid development after 1960.

الحصول على السعر

Optimizing the control system of cement milling: process ...

Based on a dynamical model of the grinding process in closed circuit mills, efficient efforts have been made to optimize PID controllers of cement milling. The process simulation is combined with an autoregressive model of the errors between the actual process values and the computed ones. Long term ...

الحصول على السعر

Optimization of Cement Grinding Operation in Ball Mills ...

The consumption of energy by the cement grinding operation amounts to one third of the total electrical energy used for the production of cement. The optimization of this process would yield substantial benefits in terms of energy savings and capacity increase. Optimization of the Cement Ball Mill Operation

الحصول على السعر

Grinding plant Fives in Cement | Minerals

Cementos Moctezuma (Mexico) Raw meal and cement grinding plants with FCB Horomill® Jingye (China) Steel slag grinding plants with FCB Horomill® Bunge Maroc Phosphore (Morocco) Phosphates grinding plant with FCB Bmill; Buzzi Unicem (USA) Cement grinding plants with FCB Horomill® Cemex (Panama) Cement grinding plant with FCB ...

الحصول على السعر

Manufacturing process | Lafarge Cement, concrete ...

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km.

الحصول على السعر