type of cement mill

Types of Cement Different cement types their uses

Aug 31, 2015· These types of coloured cement are widely used for finishing of floors, external surfaces, artificial marble, window sill slabs, textured panel faces, stair treads, etc. Expanding cement. This type of cement is produced by adding an expanding medium like sulphoaluminate and a stabilising agent to the ordinary cement.

الحصول على السعر

Taiwan Vertical Mill / Vertical Type Mill / Cement Mill ...

Vertical Mill / Vertical Type Mill / Cement Mill Model No. CPVM Made in Taiwan Supplier GREAT SUCCESS MACHINERY ELECTRICAL CO., LTD. More About This Product Discount Price Price Request for Quotation Total Price Payment

الحصول على السعر

Cement Product Information Capitol Aggregates

View Mill Certificate Product Information Safety Data Sheet. Capitol Type I(LA) cement is a general purpose construction cement suitable for all uses where the special properties of other types are not required. It meets or exceeds the requirements of ASTM C .

الحصول على السعر

Process Fans Used in Cement Industry SlideShare

Feb 23, 2016· Raw mill fans: Raw mill fan in cement industry carries gas and raw meal. The pressure drop in raw mill fan is very high. If a vertical roller mill is used for raw grinding in cement industry then a large raw mill fan is installed. Usually cement industries use centrifugal fans to carry out this process. 4.

الحصول على السعر

Mill Certificates for Suwanee American Cement Florida

Check out our Bagged Products Mill Certificates and Bulk Product Mill Certificates! Both Product Description and Document Link are provided with each Cert.

الحصول على السعر

In ADITYA CEMENT we use vertical type of roller mill in ...

In ADITYA CEMENT we use vertical type of roller mill, in past ball mill for grinding of limestone were in use but as the efficiency of ball mill was less so VRM are used nowadays. Main units of Raw mill section are as follows: (1) Vertical Roller Mill (2) Dynamic Separator .

الحصول على السعر

Cement – GCC

Oil well cement is used in the production and exploration of oil and gas wells. Class G oil well cement is used for deep wells applications. Class C oil well cement is used in shallow wells.

الحصول على السعر

Cement manufacturing components of a cement plant

The cement mill grinds the clinker to a fine powder. A small amount of gypsum a form of calcium sulfate is normally ground up with the clinker. The gypsum controls the .

الحصول على السعر

How to Read a Portland Cement Mill Test Report

through a compacted pellet of cement • Cement fineness controls early strength development • Market has driven cement fineness higher for all types over the past several decades • Fineness increases, concrete water demand generally goes up and may need .

الحصول على السعر

All Pakistan Cement Manufecturars Association

3A Low Hear of Hydration Cement (type IV of ): This is cement specially meant for the concreting of structures where large masses of concrete have to be poured at one time. Generally it is specified that heat of hydration on 7 days will not exceed 250Kg.

الحصول على السعر

Modern cement manufacturing: Cement grinding aids

Dec 04, 2008· The cement grinding aids are the additional materials (gas, liquid or solid), admixed in small amounts during the cement grinding process (cement manufacture), which can significantly improve the grinding efficiency, reduce energy consumption, without .

الحصول على السعر

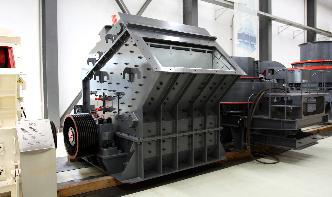

Tube Mill Internals, Shell Liners for Cement Mills

Cement – Tube mill internals – Shell liners LINERS MADE TO LAST LONGER IN CEMENT MANUFACTURING The Group Industries manufactures Inlet discharge Head, First Chamber and Second Chamber Liners to provide optimum productivity and power consumption for all types of Tube Mill used in the Cement industry.

الحصول على السعر

What are the Different Types of Cement? (with pictures)

Oct 01, 2019· Concrete is the mixture of water, some type of aggregate — such as crushed rocks or sand — and cement, which acts as a binder to hold all the materials together once hardened. Evidence suggests that the ancient Romans were the first to use the concrete mixture in construction, and structures like the Pantheon stand as proof of the success ...

الحصول على السعر

What is the use of coal in the cement manufacturing ...

Mar 29, 2017· Low grade coal can be used for cement manufacturing but it will need high grade of limestone for good quality cement. you can say low grade coal need high grade limestone and high grade coal need low grade limestone. High grade coal has less ash and low grade coal has more ash.

الحصول على السعر

(PDF) Cement Manufacturing ResearchGate

Portland cement is b y far the most common type of cement in general use around the ... Cement manufacturing process ... (1994) Cement mills along the Potomac River. Morgantown, West ia ...

الحصول على السعر

Central Plains Cement

Central Plains Cement Cement Mill Test Report June19 The current version of ASTM C 150 and AASHTO M 85 Standard Requirements

الحصول على السعر

Cement | Residential Industrial | Martin Marietta

Martin Marietta lightweight cement is a fine grind, lowdensity cement that can be mixed over a range of to pounds/gallon, and has a typical blaine surface area of 6,900 square cm/gram. For current SDS information, email .

الحصول على السعر

How to Read a Cement Mill Certificate: Part 2 NPCA

Sep 18, 2013· Calcium sulfate (CaSO4) is added to cement to control this highreactivity component (SO3 as indicated on the mill certificate). C3A is not limited in Type I cement, so when a producer labels a cement mill certificate as "Type I/II" it really means it is a Type II cement that also meets the Type I .

الحصول على السعر