how the grinding mill drive works

Innovative Gear Drive Solution for Grinding Mills | E MJ

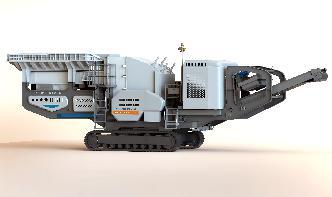

The two installed mills include a semiautogenous (SAG) mill measuring x m with a drive output of 15 MW; and a ball mill rated at 18 MW. The SAG mill reduces ore fragments with a maximum size of 250 mm (P80 = 152 mm) down to 2 mm, and the ball mill reduces the SAG mill product to about 74 µm. Grinding is followed by flotation.

الحصول على السعر

How the Roller Mills Changed the Milling Industry Angelfire

They tried to increase the number of furrows but it did not improve the product output. Even with improvements, the millstone still was slower grinding than roller mills. The roller mill became a good alternative to the progressive millers who wanted a better milling process. They wanted to improve the quality and quantity of their flour product.

الحصول على السعر

Highperforming gear unit for your ball mill

The complete central drive system delivers dependable power for raw and cement grinding – allowing your plant to operate with ease. Central power for ball mills The complete drive system for the MAAG® CPU Gear Unit works with two couplings, a main motor, auxiliary drive and an oil supply unit to ensure consistent and smooth operation.

الحصول على السعر

TECHNICAL NOTES 8 GRINDING R. P. King Mineral Tech

2. Lifters prevent slipping between the medium and slurry charge in the mill and the mill shell. Slippage will consume energy wastefully but more importantly it will reduce the ab ility of the mill shell to transmit energy to the tumbling charge. This energy is required to cause grinding of the material in the mill.

الحصول على السعر

There are three sets of instruction sheets here in this ...

Remove the top knob from the drive shaft and then the grinding mechanism from the pepper mill body. Slide the parts off the drive shaft and set aside. Clamp the drive shaft in the vise and cut the excess material off at the mark. Clamp the remaining drive shaft into the vise, the cut end up, with the end about ½" above the wooden jaws of the ...

الحصول على السعر

Solving problems on the tube mill

1. No written procedures for setup. Every mill should have written procedures for all operators to follow. The machine, tooling, and steel are fixed factors in the mill setup equation; the only variable is the human factor. This is why it is so important to have written procedures in place to control the process.

الحصول على السعر

The Grist Milling Process Pennsylvania State University

The Grist Milling Process. This vertical spindle passed through the central holes of both grinding stones without affecting the fixed stone, or bed stone, at all, but it did turn the runner stones. An iron rynd, fixed on the spindle, crossed the funnelshaped hole in the runner and had its ends firmly anchored in the upper surface of the stone.

الحصول على السعر

How to Grind Chia Seeds | Healthfully

Slowly twist the pestle, grinding the chia seeds to the consistency you need for consumption. Expect this process to take more than five minutes to get a medium grind. Pour as many chia seeds you need ground into your food processor. Most food processors can handle up to 8 cups of product or more.

الحصول على السعر

Kek Cone Mills Kemutec

Kek Cone Mill for Gentle and Intermediate Grinding "FULLY CUSTOM BUILT AND DESIGNED CONE MILLS" Kek Cone Mills are low energy and versatile mills for the gentle, intermediate grinding and deagglomeration of powders and granules. Milled Particle Size Range – D50 500µ to < 250µ Contact Us Put Us To The Test Download Brochure Features [.]

الحصول على السعر

September 2015 Glossary Grinding solutions ABB Ltd

and torque from the motor to the mill pinion. Term gearless mill drive Acronym GMD Category system Application GMD Definition System solution used in the cement and mineral industry to drive grinding mills, consisting of converter transformers, frequency converter, ring motor and auxiliaries. Especially suited for large power requirement, it has

الحصول على السعر

Prairie Mills Windmill How a Windmill Works

A windmill uses simple but effective concepts to perform its job (see illustration). In a smock mill, sails are designed similar to airplane propellers to catch the wind and spin. The sails drive the horizontal "wind shaft" and the "brake wheel" located in the top of the mill.

الحصول على السعر

Gypsum Claudius Peters

between the grinding rings. In continuous operation, a material bed forms between these balls and the grinding ring but when the mill The Claudius Peters EM Mill is the preferred grinding and calcining technology for the production of finished products such as gypsum wallboard. 4 calcining grinding

الحصول على السعر

Grinding mills. Free Online Library

Torsional vibration analysis technology has solved many problems in drive train failures on grinding mills, kilns, fans and compressors. Procurement and rehabilitation of used equipment is also within Scandinavian Grinding Mill Systems Inc.'s range of activities.

الحصول على السعر

Drive system for grinding mills Dominion Engineering ...

Nov 03, 1981· The present invention thus provides a drive control arrangement for use with a grinding mill having a drum mounted for rotation on bearing means, a driven gear secured to the drum, at least one pinion supported in driving relation with the driven gear, and electric motor means; comprising wet clutch means interposed in selective connecting relation between the motor means and the pinion, the wet .

الحصول على السعر

Stirred Milling VERTIMILL® Grinding Mills Stirred Media ...

Product from the mill exits the tank through a stand pipe and then to the cyclone sump. The slightly coarser portion of the mill overflow is recycled back into the bottom of the Vertimill. The recycle system can reduce cyclone circulating load by allowing the mill to preferentially grind the coarser material. Also, the uprising velocity in

الحصول على السعر

Cane Mills SYRUPMAKERS

Cane Mills. This is a mill that was sold by the Belknap Hardware Store and has been converted to belt power with the addition of a right angle drive and a belt pulley, for operation with a flat belt, driven by an engine or tractor. We saw this mill at Willard Moore's show in Jamestown, NC.

الحصول على السعر

Centerless Grinding: Not Magic! : Modern Machine Shop

Dec 15, 2000· Achieving consistent and quality results from the centerless grinding process requires an understanding of the basic fundamentals. Most application problems associated with centerless grinding derive from a misunderstanding of the basics. This article explains why the centerless process works and how to use it most effectively in your shop.

الحصول على السعر

CW Mill Equipment Co., Inc. |

Welcome to CW Mill Equipment Co., Inc. CW Mill Equipment Co., Inc. is a diversified manufacturing, sales, and service company. Being customerdriven is the basis for all that CW Mill Equipment does, and that approach is backed with experienced staff and advanced manufacturing equipment.

الحصول على السعر