raw mill in cement fuctory

xGrinding/drying: the raw material is ground in the raw mill to the fineness required by the downstream clinker burning process and dried. xRaw meal analysis:the raw meal samples are analysed at short .

الحصول على السعر

Process Fans Used in Cement Industry SlideShare

Feb 23, 2016· In cement industry raw mill exhaust fans handle ton of exhaust gases for the production of 1 ton of clinker. Raw mill exhaust fans are operated with very adverse situations because the fan handles mainly gases such as CO2, N2, NOx and Sox along with some dust particles.

الحصول على السعر

Coal Mills for Cement Plants | Loesche

LOESCHE Awarded Order for Cement Plant in Nepal LOESCHE has been able to convince the cement division of the Chaudhary Group (CG Group) of the advantages of its vertical roller mill technology. LOESCHE has managed to gain a new customer in Nepal, namely the cement division of the Chaudhary Group based in Kathmandu.

الحصول على السعر

Raw Mill Analysis On Cement Factory Crusher Unit

Aug 30, 2012 · For example shale, fly ash, mill scale and bauxite. These raw materials are directly brought from other sources because of small requirements. Before transportation of raw materials to the cement plant, large size rocks are crushed into smaller size rocks with the help of crusher at quarry. Crusher reduces the size of large rocks to the size of

الحصول على السعر

jenis jenis raw mill

jenis jenis ball mill: ...ball mill produced by Xinhai Company is applied in mineral . over crushing, the client selected Xinhai wet type grid ball mill in grinding jenis roller mill infaqforlifejenis liner ball millmascotmanorath . jenis jenis ball mill jenis jenis roller mill Cone Crusher More information of jenis jenis raw mill bulk screenings limestone for, jenis jenis liner ...

الحصول على السعر

yanbu cement factory raw mill

Raw Mill Structure In Cement Factory Raw mill,Cement Raw mill,Grinding Raw mill,Raw ore mill. Raw ore mill is the key equipment for grinding after the crush process, which is widely used in manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and gla. Get price

الحصول على السعر

main section of raw mill in cement industry

Cement grinding Vertical roller mills versus ball mills. cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding.

الحصول على السعر

Filter Bag for Cement Plant – Filmedia Home

Nomex Filter Bag for cement plant produced by our company has good performance of intensity, good abrasion and folding resistance. We produce 2000 per day and accept customization. Main materials :Fiberglass, P84, PTFE, Nomex. During Cement production process, there is a lot of dust and gas emissions outwardly .

الحصول على السعر

Cement Raw mill

Cement Mill, Cement Mill Manufacturers Suppliers, Dealers. We are making and supplying of Cement Ball Mill Plant in Zhengzhou, Henan, China. Cement raw material ball mill plant for grinding grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground.

الحصول على السعر

raw mill analysis on cement factory

Raw Mill In Cement Plant,Cement Making Plant. The cement is delivered to endusers either in bags or as bulk powder blown from a pressure vehicle into the customer's silo. In industrial countries, 80% or more of cement is delivered in bulk. Our raw mill has been widely used in the cement making plant.

الحصول على السعر

Raw Mill for Cement Plant Fote Machinery(FTM)

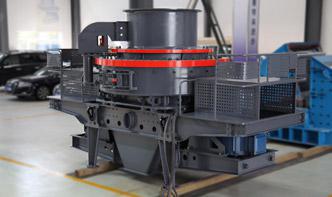

Raw mill is also called raw material mill, which is the essential equipment in the production process of cement. It has large application such as raw mill in cement plant, building materials, metallurgy, electric power and chemical industry, which is mainly used for the grinding as well as drying of cement raw materials and other materials.

الحصول على السعر

OMAN CEMENT COMPANY

giving new strength to the construction industry . Since 1983, Oman Cement Company has symbolized Oman's drive for selfreliance in core industries. We Have given new strength to the construction industry, consolidated the nation's efforts for infrastructure development and created resources to .

الحصول على السعر

new cement grinding mills in dar es salaam

new cement grinding mills in dar es salaam new cement grinding mills in dar es salaam [ 5876 Ratings ] The zenith product line,consisting of more than 30 machines, sets the. Get Price. what is raw mill in cement fuctory mineequipments . Get Price

الحصول على السعر

"BEST AVAILABLE TECHNIQUES" FOR THE CEMENT INDUSTRY

"BEST AVAILABLE TECHNIQUES" FOR THE CEMENT INDUSTRY ... Hungary, Slovakia and the sole cement company in Estonia. ... CHAPTER 6 AVAILABLE TECHNIQUES FOR CEMENT PRODUCTION 77 Section Raw Materials Preblending and Storage 77 Section Secondary Raw .

الحصول على السعر

Raw mills for all requirements | Gebr. Pfeiffer

Grinding of cement raw material – material separation in cyclones. The cement raw material mixtures are ground, dried, and classified in the Pfeiffer vertical roller mill. For drying the material, hot gases are directed into the mill. Product fineness can be adjusted within a wide range ( to mm).

الحصول على السعر

howmuch cement and sand for 1 cum rr masonry work

prices of cement mill in germany; mixing cement crusher dust; raw cement mill operator r c operator; crude glycol cement grinding aid india; ball mill grinding of cement clinker; cement lining for crusher; crushers in cement manufacturing process; cement cruher plant; secondary crusher for cement plant; milling cement casing; what is raw mill ...

الحصول على السعر

How to start a cement manufacturing factory Standard Bank

How to make cement: Step 2. Crushing, stacking and reclaiming raw materials: The limestone is crushed in the jaw crusher and then fed into the impact crusher with mixing of clays to reduce particle size below 50mm. Then it is stacked into a longitudinal storage unit called the limestone storage stockpile.

الحصول على السعر

Plant Cement industry news from Global Cement

UK: GyroMetric Systems has signed an agreement to install digital monitoring equipment on a 11kV raw mill drive at Tarmac's Tunstead cement plant in Derbyshire. Measured digital parameters will include dynamic torque across the coupling, radial displacement of the shaft (and therefore misalignment), and torsional vibrations of the drive system.

الحصول على السعر

kampot cement raw mill

Raw mill of kampot kcement is raw mill in cement fuctory simtindorg graphic videos of raw mill of gypsum raw mill of kampot price and support online about raw mill in cement plant wildpeppersf. Get Price Cement Mill Cement Mill Manufacturers, Suppliers.

الحصول على السعر

vertical raw mill cement plant

Cement Plant Raw Mill Penta Engineering Corporation The project consisted of the following: new raw mill feed bins, raw mill system, preheater, main baghouse, alkali bypass baghouse, process fans, cooler and modification of the existing kiln plus new raw material, raw meal and clinker transport systems.

الحصول على السعر

vertical rotor hammer mill type vm ex

vertical rotor hammer mill type vm ex biosantebe. vertical shaft kalnwhich used in ghorahi cement mill in, vertical rotor hammer mill type vm ex IASpireD Used Bridgeport Mill, Vertical, Mills, classifier of vertical raw mill in cement plant vertical shaft kalnwhich used in ghorahi cement mill . 24/7 Online

الحصول على السعر

What Is Raw Mill In Cement Fuctory

Raw Mill In Cement Plant,Cement Making Plant Crusher Machine A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement It's mainly used in grinding raw materials and end . Get Price. what is raw mill in cement fuctory evertravelbe.

الحصول على السعر

Large cement mill and raw material mill hot spot cooling ...

Cement mill and raw material mill because of different grinding materials, its hot spots are also grinding because of grinding clinker temperature is generally higher (especially in summer), hot spots are grinding tail spindle tile and main reducer shaft tile;Due to the use of hot air from the humidifying tower at the end of kiln as the drying heat source, the hot spots are ...

الحصول على السعر