coal jig plant

COAL BENEFICIATION

run at Satpura TPS a coal beneficiation plant at Piparwar mine of CCL was commissioned in 1997, which is supplying beneficiated noncoking coal to NTPC power station at Yamuna Nagar, Haryana and Dadri, UP. Another coal preparation plant for beneficiating noncoking coal at Bina, NCL, has also been commissioned. Installation of several more such ...

الحصول على السعر

jig coal washing plant

jig coal washing plant Coal preparation plant Wikipedia, the free . A coal preparation plant (CPP) is a facility that washes coal of soil and rock, crushes it into .

الحصول على السعر

Coal breaker Wikipedia

A coal breaker is a coal processing plant which breaks coal into various useful sizes. Coal breakers also remove impurities from the coal (typically slate ) and deposit them into a culm dump . The coal breaker is a forerunner of the modern coal preparation plant .

الحصول على السعر

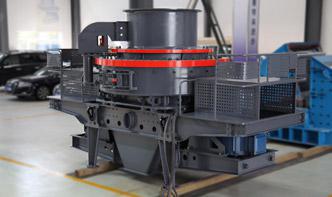

Coal Jigging Machine Wholesale, Jig Machine Suppliers ...

Instruction Coal Cleaning Plant is widely used to clean raw coal. is located in Zhengzhou National HiTech Industrial Development Zone, Henan Province. Our company has passed ISO9001 international quality system certification.

الحصول على السعر

Modular Plants Portaclone modular coal plants

Modular Plants. THE WAY TO GREATER FLEXIBILITY. Many years ago we recognized the need to have flexibility built into the design of coal beneficiation plants. During its long lifetime a plant will likely encounter widely varying feedstock from different seams and the market requirements for the products will undoubtedly continue to change.

الحصول على السعر

We've Improved Coal Quality New LC3 Low Cut Point Spiral

Coal; Process Solutions. Metallurgical Testing Process Design; Equipment Design Selection. Gravity Separation; Centrifugal Jig Technology; Electrostatic Separation; Magnetic Separation; Shaking Tables, Knudsen Bowl; Process Audits Optimisation; New Products from RD; Plant Design. World's Largest Mineral Sands Plant Design; Innovative Iron Ore Tailings Plant Design

الحصول على السعر

Life Cycle Assessment of Coalfired Power Production

The Average coal power plant consists of the following main equipment/process steps: pulverized coal boiler, baghouse filter, conventional limestone flue gas cleanup (FGC) system, heat recovery steam generator, and steam turbine (see Figure 4). The emissions for this system represent the average emissions from all coalfired power plants in 1995.

الحصول على السعر

Coal Processing Plants | Coal Processing | Star Trace Pvt ...

Coal Processing Plants. Star Trace offers turnkey solutions for coal processing plants. We are one of the leading project suppliers for zircon plants and we work closely with our customers to fulfill their specific needs for a customized packaged solution.

الحصول على السعر

Mineral Jig Concentrators for Ore Processing Separation ...

Aug 14, 2018· If a jig concentrator is being used for minerals that are lower in density, coal being one, the gravitational energy has a reverse effect because material around coal is heavier and the coal will ...

الحصول على السعر

Appendix E: Coal Mining and Processing Methods | Coal ...

Underground Mining. The surface features shown are the raw coal storage silo fed by the slope conveyor, the coal preparation plant (the building on the left), the clean coal storage silos in the front, and the train load out. A longwall section and a roomandpillar continuous miner section are shown.

الحصول على السعر

One Vision Coal Washing Plant YouTube

Jun 30, 2014· The first commission of a 100tph coal washing plant in Zimbabwe. The plant consists of a feed arrangement (hopper, plate feeder and belt), a 100tph mechanical jig with product and tails dewatering ...

الحصول على السعر

Altair jig: an inplant evaluation for fine coal cleaning ...

The fine coal cleaning performance of the Altair centrifugal jig was evaluated in an actual plant environment by treating a nominally 1 mm coal stream, which feeds the fine coal cleaning circuit of a preparation plant.

الحصول على السعر

MOBILE COAL PROCESSING PLANTS Mine Equipments

Coal Preparation Plant mobile coal preparation plant,mining coal crushing plant in south africa for sale. US / Set ( FOB Price). 1 Set (Min. Order). 100 Set/Sets per Month ...

الحصول على السعر

DRY PROCESSING OF 4 mm COAL FINES THROUGH AIR JIG and ...

DRY PROCESSING OF 4 mm COAL FINES THROUGH AIR JIG and AERODYNAMIC SEPARATOR. It was found that air jig was superior to aerodynamic separator based on the concentrate quality and separation efficiencies. Concentrate ashes at around 20 and 25 % were obtained with air jigging and aerodynamic separator, respectively.

الحصول على السعر

How jig's works and how to wash coal using Jig's. YouTube

Dec 22, 2016· these jig's work on pulsation and suction theory. mostly use for coal washing. these jig's work on pulsation and suction theory. mostly use for coal washing. Skip navigation Sign in.

الحصول على السعر

Producing Clean Coal from Western Canadian Coalfields ...

from the jig vessel, thus allowing the water to drain from the coal. A sample pusher was inserted in the jig tube and pressed to allow more water to drain. The entire tube was then inverted to allow the coal to be pushed upward. Once the jig tube was inverted and the screen removed, the marbles were visible, as they had the heaviest specific ...

الحصول على السعر

The Principles of Coal Preparation

The Principles of Coal Preparation . 4 th Edition 2007 . G J (Joe) Sanders . Table of Contents . 1 Coal in the Ground . Introduction . The Coalification Process . Peat Formation . Coal Seam Formation . Theories of Deposition . Coalfield Formation . "Gondwanaland" The Nature of Coal . Rank and Type of Coal

الحصول على السعر

how does a coal washing plant work[mining plant]

A CPP may also be called a coal handling and preparation plant (CHPP), prep plant, tipple, or wash plant. Coal Preparation Plants. Thermal dryers are fired with coal, oil, or gas. Jigtable Washing Jigtable washing plants are so named ...

الحصول على السعر

Coal Beneficiation Technology for Coking NonCoking Coal ...

A coal preparation plant (CPP) is a facility, washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing. A CPP may also be called a coal handling and preparation plant (CHPP), The more of this waste material that can be .

الحصول على السعر

Coal Preparation Plant Simulation (Software) |

The desired degree of coal preparation depends on the estimated costs and potential benefits associated with the entire process. Three hypothetical coal preparation plants have been designed to provide a basis for preliminary cost estimates. These are a crushing and screening plant, a Baum jig plant, and a heavymedia plant.

الحصول على السعر

Centrifugal Jig Technology Mineral Technologies

Kelsey Jigs are effective at processing minerals such as zircon, rutile, tin, tantalum, tungsten, gold and nickel. In addition, testwork has achieved positive results for chromite, iron ore, niobium, base metals (Pb, Zn, Co, Cu) and other applications.

الحصول على السعر

Coal Washing Jig, Coal Washing Jig Suppliers and ...

offers 200 coal washing jig products. About 38% of these are mineral separator, 3% are other mining machines, and 1% are other food processing machinery. A wide variety of coal washing jig options are available to you, such as gravity separator, sprial separator, and magnetic separator.

الحصول على السعر

DELKOR APIC Jigs | TENOVA

A DELKOR APIC jig was supplied as part of a contract to provide plant engineering for the complete crushing, screening and jigging plant for iron ore beneficiation. The jig, was at the time of the contract, the largest in the iron ore beneficiation industry in India, and is an important reference for 4 m wide APIC jigs.

الحصول على السعر

Table of Contents

19 Coal Processing Transfer Jig Plant to Conveyor 4 350 tph TBD 20 Coal Processing Transfer Conveyor 4 to Clean Stockpile 350 tph TBD 21 Coal Processing Transfer Clean Stockpile to .

الحصول على السعر

What Is Coal Preparation? Energy

Coal to Electricity "Heat Rate". • The average heat rate is approximately 10,000 Btu (2,520 kcal) per kilowatthour generated. This number will vary depending upon the type of boiler, heat exchangers, auxiliary power consumption etc. but the efficiency of most plants in .

الحصول على السعر