coal grinding methods

Recycling of Coal Ash in Concrete as a Partial ...

To make better use of CBA, the mechanical grinding method can be utilized to get a finer particle size. Therefore, this study evaluated the ground CBA particle fineness e ects on the concrete properties. 2. Materials and Methods Materials The ordinary Portland cement (OPC) TypeI was used as main binding material along with

الحصول على السعر

Mining Industry Profile | Department of Energy

Production and Supply. Approximately 66% of coal and 97% of nonfuel minerals are extracted through surface mining methods. Both mining methods go through a process involving three general stages. The first stage is extraction, which includes blasting and drilling to loosen and remove material from the mine.

الحصول على السعر

What is the most appropriate grinding mill type for coals ...

All Answers ( 7) The layout of a coal grinding system must take into account the available heat sources for drying the raw coal as well as the fire and explosion hazards of coal and coal dust. The entire grinding plant must therefore be shockresistant and equipped with a number of explosion relief valves. When grinding lowexplosive...

الحصول على السعر

Mining Industry: What is a coal mill? Quora

Jun 30, 2019· Coal mill is an important auxiliary equipment for coalpowder furnace, it has three methods to crush the coal lump and grind them into powder,it is crushing, impacting and grinding. Air swept coal mill is the main equipment in cement plant for both drying and grinding of the powders.

الحصول على السعر

Æ Grinding Methods Barista Hustle

Æ Grinding Methods. Please sign up for the course before starting the lesson. Æ Grinding Æ Grind Size Back to: Advanced Espresso – Lessons Published Biweekly > Æ Grinding. October 2019; Mon Tue Wed Thu Fri Sat Sun; 1. 2. 3. CO: Barista One in Medellin

الحصول على السعر

Generation of low ash fine clean coal powder by autogenous ...

Jan 15, 2019· In conventional coal grinding process, coal is grinded mainly using the hammer mills, where due to the high impact force, the maceral and minerals homogenously due to breakage function [,, ]. It was shown that, the crack generation completely depends on the impact given during the grinding process . After grinding, the state of coal is changed: grain size, grain size disposition and grain shape.

الحصول على السعر

Coal Mining and Processing | Energy Trends Insider

Many coal beds are very near the ground's surface, and about twothirds of coal production comes from surface mines. Modern mining methods allow us to easily reach most of our coal reserves. Due to growth in surface mining and improved mining technology, the amount of coal produced by one miner in one hour has more than tripled since 1978.

الحصول على السعر

Effect of Wet Versus Dry Grinding on Rejection of Pyrite ...

Majority of the recent investigations on flotation of fine coals have been conducted. with coal feeds obtained by either dry grinding or wet grinding. 11 Therefore, the. effect of different grinding methods on the separation of coal from pyrite from other ash forming minerals is not clear from these studies.

الحصول على السعر

Method of simultaneously grinding coal and dolomite ...

Feb 10, 1987· 5. A method of simultaneously grinding coal and dolomite, each having different hardness characteristics, in a common grinding mill having a grinding chamber and impact hammers on a grinding rotor, which method comprises the steps of: (a) supplying coal and dolomite to the grinding chamber;

الحصول على السعر

Mining Industry Profile | Department of Energy

The mining industry consists of the search for, extraction, beneficiation, and processing of naturally occurring solid minerals from the earth. These mined minerals include coal, metals such as iron, copper, or zinc, and industrial minerals such as potash, limestone, and other crushed rocks. Oil and natural gas extraction (NAICS code 211) is not included in this industry.

الحصول على السعر

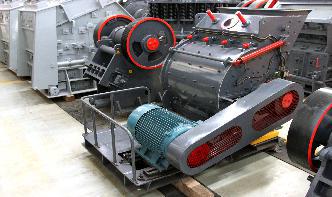

impact coal crusher balancing method | worldcrushers

Impact Coal Crusher Balancing Method Crushing Plant In China Crusher Sand 4000 Mesh Micro Powder Grinding . Coal mining process inclurock coal crushing, Grinding and . SBM is ready to provide you with coal .

الحصول على السعر

Spontaneous combustion of coal SlideShare

Nov 03, 2014· •Any grinding of coal along the fault plane may lead to selfheating. g. Coal friability •Friable coals tend to produce coal fines which, due to larger surface area, have a greater tendency to sp. combustion. 33. 3. Mining Factors a. Mining methods •Longwall advancing leaves extracted areas lying between the entries serving the working places.

الحصول على السعر

Particle Size Analysis for Mining and Minerals ...

Extracting useful minerals is an arduous and technically demanding process. First, any material on top of the deposit, known as overburden, must be removed or tunneled through. In the next step, the ore is blasted or cut and loaded and hauled to the mill for the secondary crushing and grinding which prepares the material for its intended use.

الحصول على السعر

Dust Sampling Instrumentation and Methods

Sep 28, 2010· Method 7500) • Sufficient mass must be collected to have confidence in measurement • NIOSH typically uses multiple gravimetric samplers and averages data

الحصول على السعر

Mining Industry Energy Bandwidth Study

Diesel fuel accounts for 34% of the mining industry's fuel needs, followed by onsite electricity at 32%, natural gas at 22%, and coal and gasoline supplying the balance (Exhibit 4).7 The type of fuel used at a mine site will depend on the mine type (surface or underground) and on the processes employed.

الحصول على السعر

Coal mill pulverizer in thermal power plants SlideShare

Nov 17, 2012· coal mill/pulverizer in thermal power plants shivaji choudhury 2. Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in pulverized form. Pulverized coal achieved its first commercial success in the cement industry.

الحصول على السعر

CoalFired Power Plant Heat Rate Reductions

methods to reduce the heat rate of existing coalfired power plants in a range of sizes−200 MW, 500 MW, and 900 MW. The primary intent of the study was to focus on methods that have been successfully implemented by the utility industry.

الحصول على السعر

Sample preparation for coal analysis

coal samples, such as brown coal, the sample preparation step becomes even more important in ensuring reproducible analysis results. The fineness of the sample can influence the standard deviation of the analysis results, as will be shown in this article using brown coal as an example. In general, using a sample divider to

الحصول على السعر

Ball mill Wikipedia

The ball mill is used for grinding materials such as coal, pigments, and feldspar for pottery. Grinding can be carried out either wet or dry but the former is performed at low speed. Blending of explosives is an example of an application for rubber balls.

الحصول على السعر

milling machine coal grinding position and working process

milling machine coal grinding position and working process 8572 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. Mill (grinding) Wikipedia. A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit ...

الحصول على السعر

Maritime Guidance Documents | Abrasive Blasting Hazards in ...

Chipping, grinding, sanding, or scraping the coating off small parts or surfaces through the use of needle guns, chipping hammers, sanders, and grinders. Some power tools may be equipped with dust collection systems. Generates paint waste and airborne particulate .

الحصول على السعر