primary crusher crusher

Primary C3055 Jaw Crushing Station (#005018) – J ...

Home / Jaw Crushers / Primary C3055 Jaw Crushing Station (#005018) Primary C3055 Jaw Crushing Station (#005018) Categories: Jaw Crushers, Recycling Equipment

الحصول على السعر

Crushers and Their Types – IspatGuru

Apr 03, 2015· Jaw crusher Jaw crusher is used as primary crusher. It uses compressive force for breaking the material. This mechanical pressure is achieved by the two jaws of the crusher. Reduction ratio is usually 6:1.

الحصول على السعر

Primary crusher Mining Machinery

The primary crusher has the characteristics of high crushing ratio, uniform product strength, simple mechanism, and reliable operation. It is widely used in metal and nonmetal, cement, construction, sand, metallurgy and other industries. The primary crusher can process 200 kinds of mineral ores in the primary and coarse crushing process, such as granite, basalt, limestone, rock, concrete, aggregate, gravel, .

الحصول على السعر

Primary Crusher Wholesale, Crushers Suppliers Alibaba

Jaw crusher, the most popular crusher in traditional crushing production line, is always used in both primary and secondary crushing. CFC is a professional contractor to build the projects of large crushing and screening production line, mine grinding production line, all kinds of metal dressing production line, dust air purification and so on.

الحصول على السعر

PE Jaw Crusher Machine, Small Jaw Crusher Price, Stone ...

Primary jaw crusher, refers to PE jaw crusher, is the first crusher that is used during the crushing process. The primary jaw crushing machine, also named as PE jaw crusher machine, can crush all kinds of mineral ores or stones into particles with medium size.

الحصول على السعر

Primary crusher | Article about primary crusher by The ...

Because the hopper would often empty between truckloads, coal would flood the primary crusher as the truck dumped its load. HBMS engineers had identified the primary crusher as a bottleneck as it suffered regular downtime caused by oversize in the feed.

الحصول على السعر

Lancaster Products Roll Crusher for Glass Manufacturing

Lancaster Products Roll Crushers are designed for long life with a minimum of maintenance. These crushers reduce – in a single pass material previously requiring primary and secondary crushing. The crushing rolls turn toward each other, confining all crushing to the area where the teeth mesh.

الحصول على السعر

AP42 Section Crushed Stone Processing and ...

boulders from finer rocks that do not require primary crushing, thus reducing the load to the primary crusher. Jaw, impactor, or gyratory crushers are usually used for initial reduction. The crusher product, normally to 30 centimeters (3 to 12 inches) in diameter, and the grizzly

الحصول على السعر

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1. Feed: ROM up to m; Product: 300mm (for transport) to 200mm (for SAG mill) Feed Rate: 160 to 13,000 tph; The family of primary crushers include:

الحصول على السعر

Primary and secondary cone crushers Uralmash

Primary and secondary cone crushers Secondary and tertiary cone crushers Jaw crushers Crushing and handling plant DPU1000 Mills Primary and secondary cone crushers The company produces wide range of primary and secondary crushers with feed opening size from 500 to 1500 mm.

الحصول على السعر

Impact Crushers | Equipment For Sale or Lease | Frontline ...

Track Mounted Impact Crushers for Sale Rent Mobile Impact Crushers. Frontline offers an extensive selection of Keestrack GIPO track mounted mobile horizontal shaft impact crushers suitable for primary and secondary crushing applications including soft, medium hard stone, concrete construction debris, quartz glass and asphalt recycling (RAP).

الحصول على السعر

Primary Crushing Stations | LippmannMilwaukee

Dual 5062 Primary Station Twin Primary Jaw Crushers – A cost efficient mining industry new technology alternative to conventional gyratory primary crushing stations for high volume processing of .

الحصول على السعر

Mine Crusher

Dec 13, 2011· To the jaw crusher, we adopt heavy movable jaw and optimized connect methods, in this way, the hard mining ores can be crushed easily. Obviously, jaw crushers are just primary crushers, they can crush big lumps to small lumps, but the products .

الحصول على السعر

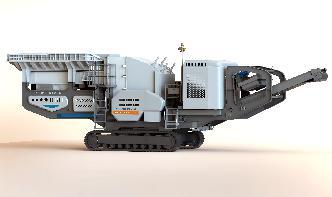

Mobile Jaw Crushing Plant

mobile jaw crushing plant includes hopper, vibrating feeder, jaw crusher, semitrailer chassis, and other supporting parts. Its production process is as follows: materials are fed into hopper firstly; then vibrating feeder prescreens materials; then large materials will be fed into jaw crusher for primary crushing; then crushed materials will be carried out by belt conveyor.

الحصول على السعر

Primary Crushing Best Maintenance Practices and Application

• Jaw Crusher – A crusher that breaks material by squeezing it between two Jaw plates, one Moving and one stationary. • Crushing chamber – Space between the stationary and the moving jaw. • Gap – Top opening dimension of the jaw crusher from the stationary jaw to the pitman. • Close side setting

الحصول على السعر

ABM Primary Crusher

The main crusher housing, internal concrete chutes and main crusher roof platform were formed and poured in one to achieve the integral strengths as designed. On completion a 125 tonne primary crusher was installed on the roof platform along with associated services, conveyors, housings and plant.

الحصول على السعر