wear in vertical mill

MPS vertical roller mill Gebr. Pfeiffer

The highest wear occurs on the wear parts of the grinding elements as is the case with any type of vertical mill. Therefore, ease of replacement and regeneration is a major feature of the mill. With our proven LiftandSwing System, wear parts can be replaced rapidly through one single maintenance door.

الحصول على السعر

Safety Measures to Use While Operating Milling Machines

Nov 13, 2014· Wear appropriate safety glasses and ear protection while operating the machine. This will reduce the risk of injuries to your eyes or hearing loss since the machine can operate in excess of 70 dB. Noise levels in excess of 90 dB can cause hearing loss after prolonged exposure, according to the CDC.

الحصول على السعر

Coal Crushers | Coal Pulverizers Mills | Williams Crusher

Pulverizers Coal Grinding Roller Mills William's Vertical Roller Mill Pulverizers utilize centrifugal force to grind coal material while maintaining low operating costs. Featuring easily replaceable wear parts, automated process controls and infinite turndown thanks to VFAC drives, these machines are perfect to use as a coal mill.

الحصول على السعر

Component wear in vertical spindle mills grinding coal ...

Component wear in vertical spindle mills grinding coal Component wear in vertical spindle mills grinding coal Sligar, J. 00:00:00 This paper reports on the contribution of a number of material coal properties and machine operating parameters to the wear of vertical spindle mill components. This assists in the evaluation of mills and coals for particular duties and enables .

الحصول على السعر

Component wear in vertical spindle mills grinding coal ...

Pulveriser effects The prime factor in the effect of mill mechanics on component wear is the roll grinding pressure followed by the rate of recirculation within the mill which is controlled by the vane setting in the cyclone at the mill outlet.

الحصول على السعر

Influence of quartz particles on wear in vertical roller ...

Quartz is a hard mineral frequently being part in cement raw mixes. Hence it is of interest to correlate its content in the mixture with the wear rates experienced in vertical roller mills (VRM). From the experience of numerous laboratory VRM tests, it is known that the measured wear rates might not correlate with wear rates in full scale VRMs.

الحصول على السعر

Feedscrew wear vertical mill | Model Engineer

Nov 03, 2016· Mill is from the 1940s and I just happened to secure vice in centre of table, no doubt the most used portion. At this point I can push table to and fro slightly, taking up wear between pitch, when I move table to the far end of its travel there is no movement so I am assuming this points to feedscrew wear and not the half nut?

الحصول على السعر

Introduction to Milling Tools and Their Application

©2016 MachiningCloud, Inc. Milling is done using a cylindrical milling tool mounted in a milling tool holder that is then mounted in the tool spindle on the machine. End mills are the most common milling cutters. End mills are available in a wide variety of lengths, diameters, and types.

الحصول على السعر

Introduction to Milling Tools and Their Application

End mills are made out of either cobalt steel alloys (known as high speed steel, or HSS), or from tungsten carbide in a cobalt lattice (shortened to "carbide"). High Speed Steel (HSS): Provides good wear resistance and costs less than cobalt or carbide end mills. HSS is used for general purpose milling of both ferrous and nonferrous materials.

الحصول على السعر

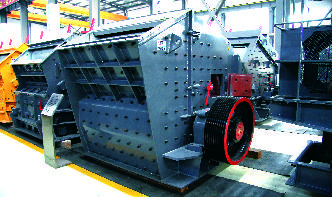

coal vertical mill wear parts

Vertical Mill Spare Parts Taiwan Trade We provide varieties of Vertical mill wear parts. such as grinding rollers and disc . These mills are raw material mill, clinker mill and coal mill in cement plant .

الحصول على السعر

Milling (machining) Wikipedia

There are two subcategories of vertical mills: the bed mill and the turret mill. A turret mill has a stationary spindle and the table is moved both perpendicular and parallel to the spindle axis to accomplish cutting.

الحصول على السعر

Vertical Mill Table Roller Liner Wear Assessment

Maintenance of Cement plant vertical roller mill wear . The cement vertical roller mill design . Maintenance of Cement plant vertical roller mill wear . of both the table and roller liners. The actual wear rate for . Get Price And Support Online; MPS vertical roller mill Gebr. Pfeiffer. The MPS vertical roller mill .

الحصول على السعر

41 Vertical Mills_V20 | Mill (Grinding) | Gases Scribd

Vertical Roller Mills. Vertical Roller Mills. The term Vertical Mill denotes equipment with the following characteristics A rotating, circular grinding table that turns around a vertical shaft Spherical, cylindrical, tapered rollers that are pressed on to roller paths on the surface of the table. A .

الحصول على السعر

Vertical Roller Mill Wear Parts PEW Jaw Crusher

Vertical roller mill has many wear parts. These wear parts include grinding roller, grinding millstone, classifier vane and other wear parts. This article will introduce the vertical roller mill wear parts from the function and texture of material.

الحصول على السعر

Cement Vertical Mill Wear Rate

Maintenance of Cement plant vertical roller mill wear parts. The actual wear rate for both the roller and table liners before hardfacing was g/T. The measured wear rate with hardfaced liners was g/T. The 50% reduction in wear rate with hardfaced liners was expected as data from other vertical cement mills indicated such a savings ...

الحصول على السعر

vertical roller mill Cement industry news from Global Cement

Turkey: Engineering supplier Loesche has released information about a contract it signed in July 2013 to supply Göltas Cimento with a Type LM +3 vertical roller mill for cement grinding for its plant 130km north of Antalya. Loesche has previously supplied the company with vertical roller mills for cement raw material and coal grinding.

الحصول على السعر